Plug & Work ─ Now Available For Cobots From OMRON and FANUC

Aug 6, 2021

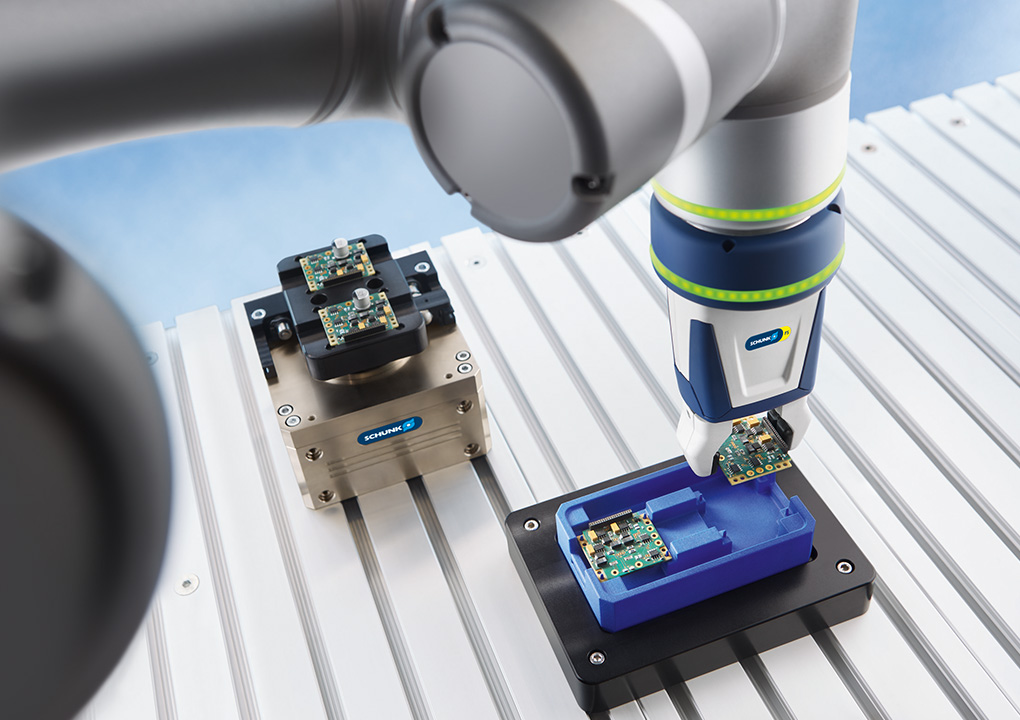

Cobots have decisively shaped industrial robotics in recent years ─ and they have become increasingly popular. To enable users to work quickly and easily with the industrial lightweight robots, SCHUNK is expanding its Plug & Work portfolio to include perfectly matched standard components for lightweight robots from OMRON and FANUC. This is an expansion of the Plug & Work options already available for Universal Robots, Doosan Robotics and Techman Robot. These solutions can be used to implement diverse automation scenarios in a very short time.

Cobots are lightweight, flexible to use, and easy to program. They can be used to automate repetitive tasks, such as machine loading and unloading or assembly, quickly and cost-effectively. It is therefore no wonder that they are now an integral part of industrial robotics and are becoming increasingly important. Even small and medium-sized companies are increasingly automating their production and logistics tasks. To make it as easy as possible for users to equip their new helper, SCHUNK offers comprehensive complete programs for cobots and lightweight robots from various manufacturers. The Plug & Work portfolio includes pneumatic and electric grippers, Co-act gripping modules for collaborative applications, and quick-change systems.

Components and direct connection for numerous manufacturers

In addition to the ready-to-connect portfolio for Universal Robots, the competence leader for gripping systems and clamping technology has also been offering simple equipment for lightweight robots from Doosan Robotics and Techman Robot since the end of 2020. Now it is adding further manufacturers to its Plug & Work offering: Beginning in August, components for OMRON and FANUC robots will be part of the portfolio. Among others, SCHUNK offers the EGH universal gripper with a freely programmable overall stroke of 80 mm and the collaborative gripper for small components Co-act EGP-C for both manufacturers. SCHUNK also supplements the EGP-C with a direct connection to lightweight robots from YASKAWA and Mitsubishi Electric. The expansion to other cobot manufacturers will follow.

Development of the concrete robot application in the CoLab

Development of the concrete robot application in the CoLab

The standardized components of the Plug & Work portfolio cover a variety of applications for lightweight robots, from quality inspection to assembly and handling to machine loading and unloading. The experts in the CoLab robot application center help with the development of individual customer applications. Together with the customer, they put together the right components for the specific cobot application and test their use and feasibility. Eighteen industrial robots and cobots as well as specially equipped cells for lightweight design, industrial robots and test setups are available now for this purpose. SCHUNK is not only offering a comprehensive portfolio of perfectly matched grippers and quick-change systems for robots from various manufacturers to its customers, but also the appropriate application know-how. This allows professionals and automation beginners alike to tap the potential of cobots for their applications.

Download the press release by visiting the website, here schunk.com/ca_en/