AutoSorter XN Provides Pre- and Post-Analytic Specimen Processing for Sysmex XN-Series Line

April 29, 2021

Specifically designed for the Sysmex XN-Series hematology line, AutoSorter XN is a robust robotic platform for pre- and post- analytic specimen processing in demanding laboratory environments. Well-suited for high-volume commercial lab requirements such as bulk loading and high-speed specimen sorting, AutoSorter XN is capable of loading/unloading a fully populated line at capacity, processing up to 1,100 specimens/hour.

Built to industrial standards, robots and components are proven to produce extremely high system uptime and reliability for movement of specimens within the workcell. A large sort deck maintains increased quantities of specimens for fully automated workload balancing, yielding extended walkaway times and freeing workers from non-value-added processing tasks.

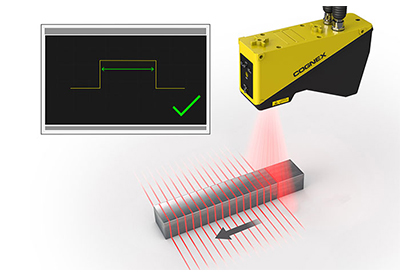

AutoSorter XN features hopper loaded input, accommodating specimen tubes 13 mm x 75 mm. Powerful vision technology determines tube orientation and checks for label positions, while the specimen ID (SID) is compared to a database for processing instructions. Conforming specimens are placed into corresponding target racks or to a 10-position Sysmex rack to be conveyed to the XN hematology line. When testing is complete, all racks are conveyed back to the AutoSorter XN for tube unloading and post-analytic sorting into output racks and drawers based on LIS instructions (archive or secondary sort).

Traceability of each specimen is accurately maintained throughout the system including the target rack, row/column location. IT connectivity facilitates sort instruction and archive log data.

Yaskawa provides automation solutions for labor-intensive, high throughput areas of the clinical diagnostic laboratory. Capabilities include sorting; aliquoting; decapping/recapping; thawing/mixing; centrifugation; and archive storage and retrieval – with a range of standard platforms. AutoSorter solutions can be customized to meet every laboratory’s unique specimen processing needs.