Schmalz: The Perfect Gripper With Just Four Tools

April 15, 2021

Less is more. This statement also applies to Schmalz’s new PXT modular gripper system. Because users can assemble their gripper quickly and easily from just a few standard components – and even assemble it themselves if they wish.

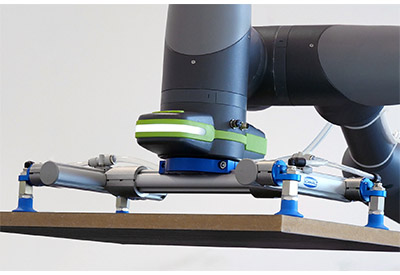

The PXT gripper construction kit is a lightweight and modular gripping system for lightweight robotics and is compatible with the most common robot systems. With this construction kit, the user can assemble end effectors for many applications from a well thought-out selection of high-quality standard components. All he needs to assemble them is a cross-cut saw, spanner, drill and Allen key – nothing more. Optionally, Schmalz also supplies the fully assembled system.

The self-configured gripper handles workpieces weighing up to 25 kilograms. Schmalz thus closes the gap between the VEE with a payload of up to two kilograms and the Schmalz Tooling System SXT, which is designed for loads over 25 kilograms. The largest gripping area is 800 x 600 millimetres. The gripper is so flat that it can also be used for removing injection moulds without any problems. Thanks to optional internal vacuum guidance, the modular system does not need any external hoses. Thanks to the reduced interfering contours, the grippers can be used even in the tightest spaces. The individual components can always be recombined or adjusted if the geometry of the objects to be supported changes. The connection elements are designed in such a way that users can integrate all Schmalz components, such as larger suction cups.

The PXT modular gripper system is suitable for a wide range of palletising and handling tasks and can be used in all industries – from the food industry to the automotive sector to logistics. The gripper can be used to pack yoghurt pots from machines into crates, to handle sheet metal parts or to palletise cardboard boxes.

The new PXT modular gripper system consists of robot flanges for the most common lightweight robots, standard crossbars and profile tubes, cross connectors and connecting elements, cover caps for the profile tubes as well as retaining and connecting elements for spring plungers and suction pads. Ordering is as simple and flexible as the system itself: users create their gripper themselves in the online configurator. Schmalz then delivers the fully assembled system or the individual parts for self-assembly.