SINAMICS G115D – The Distributed Drive System

March 19, 2021

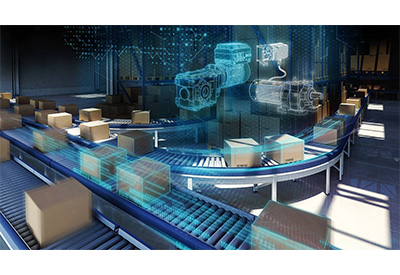

Innovative system solutions for horizontal motion applications

The SINAMICS G115D is a powerful drive system that has been specifically designed to address current and future challenges involving horizontal conveyor applications. Typical applications include intralogistics and airports. These markets face challenges such as the volume of demands and parcel shipments, and in environments where space is at a premium. This means that a higher volume must be handled in a shorter time. SINAMICS G115D is the optimum device when addressing all of these requirements as it operates reliably under harsh conditions and takes up little space. It combines a motor, frequency converter and gearbox in one single unit. This all-in-one solution means that it can be easily integrated into existing automation environments.

The story of SINAMICS G115D: Two versions of one drive system

SINAMICS G115D is not just a new distributed drive, but a complete drive system. The SINAMICS G115D comprises a motor, frequency converter and gearbox and is available in two versions. This user-friendly, modular and versatile solution offers dedicated features for conveyor applications, and has an innovative design to make connecting up, commissioning and service very easy. With SINAMICS G115D, you benefit from an out-of the-box concept for easy handling, fast set-up and extremely simple operation.

Distributed drive system improvements

SINAMICS G115D represents the innovative distributed drive system packed with completely new features.

SYSTEM CONCEPT

- – The SINAMICS G115D drive system has just one order number, is ready-to-run out-of-the-box and it is very compact. It is easy to select, easy to install and easy to operate.

- – One system platform with the same look and feel, available in two versions to precisely fit your application: Motor mounted and Wall mounted.

- – Energy efficient concept: Motors are available either with efficiency class IE3 or IE4, allowing the drive system to address markets around the world with the same level of performance.

EASY-TO-USE

- – Fully integrated into a powerful automation tool: Startdrive/TIA Portal – ensures high degree of user friendliness and intuitive interaction with the automation layer.

- – lntegrated firmware with embedded conveyor functions guarantees shorter commissioning times and therefore lower costs.

- – Wi-Fi web server via SINAMICS Smart Access Module facilitates easy commissioning and diagnostics from a mobile device (e.g smartphone, tablet or PC).

PACKED WITH EVEN MORE FUNCTIONS

- – Fit for digitalization: all SINAMICS G115D drive system parameters can be transferred to MindSphere via PROFINET.

- – Wider temperature range down to -30°C makes the drive system the optimum choice even for operation in warehouses handling frozen goods.

- – Safety Integrated: Safe-Torque-Off (STO) function is integrated as standard and offers control via F-DI and PROFIsafe.

- – Improved diagnosis thanks to additional onboard LEDs, local remote control and repair switch with feedback to adapt to customer requirements.

Specific functions for a wide range of applications

SINAMICS G115D is more than just another frequency converter. lt is an optimally matched system solution comprising a high-efficiency geared motor and an innovative, low profile frequency converter. The system has been optimized exclusively for energy and cost efficient horizontal motion in applications such as conveyor belts, sorting systems, baggage and freight conveyor systems, warehouse and distribution logistics, mail sorting as well as parcel distribution. It has been specifically designed to address intralogistic and airport applications, but also in the automotive and F&B domains.

SINAMICS G115D is versatile, rugged and distributed

Versatile

- – SINAMICS G115D stands for easy configuring, easy ordering and easy commissioning. As a comprehensive distributed drive system, it is the simple solution to address the challenges of horizontal conveyor applications.

- – Fully implemented in the Totally lntegrated Automation (TIA) environment, which seamlessly integrates hardware, software and services. All of the individual components are harmonized and coordinated with one another.

Rugged

- – Rugged design that has a high IP degree of protection (up to IP66). This makes it ready to use in harsh environments, but as a result of its compact design it can be used in applications where space is at a premium.

- – Reliable operation over a wide temperature range extending from -30 to 55°C.

Distributed

- – The SINAMICS G115D drive system belongs to a family of distributed converters.

- – The distributed system approach allows motors to be controlled close to the actual application, reduces the number of motor cables required, improves electromagnetic compatibility and reduces thermal losses.

SINAMICS G115D meets the requirements of digitalization

Our distributed drive system is cloud-connected

In every state-of-the-art intralogistics solution, integration into higher level automation systems is essential to be able to achieve maximum flexibility and efficiency. With SINAMICS G115D you benefit from seamless integration both in the TIA environment (for higher level automation) and in MindSphere applications such as Analyze MyDrives (for single drive optimization).

With this underlying system of checks and analyses, horizontal conveyors are even able to utilize web-based platforms to become part of a networked industry, taking full advantage of the loT.

The number of products conveyed can be ideally monitored using the MindSphere app Analyze MyDrives. lt provides a comprehensive overview of the system’s performance and material flow, and enables users to ensure high levels of availability. Based on the results, workflows can also be streamlined, failures can be predicted and prevented, and maintenance can be performed when it is convenient – not just when necessary.