Festo Introduces the VAEM Valve Controller for Multi-Head Liquid Dispensing

November 26, 2020

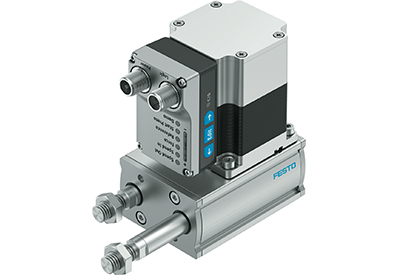

VAEM valve controllers are suitable for 2/2- and 3/2-way solenoid valves.

In March of 2020, Festo introduced the VAEM valve solenoid controller for multi-head micro-dispensing in pharmaceutical manufacturing and laboratory applications that require high speed and a low coefficient of variation (CV). The compact and energy efficient VAEM provides individualized control and calibration of to up to eight solenoid valves.

“As our life science technologists were designing the next generation of Festo multi-head micro-dispensing systems, they found that a more advanced valve controller was required, one that would meet their speed and precision goals,” said Craig Correia, Director of Life Science & Process Industries, Festo North America. “As development on the new valve controller progressed, the team also designed in energy efficiency, minimal heat generation, ease of use, compactness, and importantly, the capability to compensate for flow variations in individual valves.”

The VAEM valve can open a valve in under 2 milliseconds. Rapid and precise control of the valve decreased CV from 3% to less than .5% in laboratory benchmark testing. The VAEM enables users to easily and quickly calibrate flow through individual channels, which improves precision across multi-head systems.

The VAEM employs a “hit and hold” strategy to lower energy consumption. A short burst of high current “hits” the open position, and then the VAEM switches to a minimum current to “hold” the open position for a specified time. The strategy of using current rather than voltage to control valves diminishes heat buildup and aids in maintaining specified flow.

VAEM valve controllers are suitable for 2/2- and 3/2-way solenoid valves. They feature RS232 communication. Future iterations of the valve controller will have options for Ethernet, Modbus TCP, and IO-Link. A PC based graphical user interface (GUI) enables users to pre-calibrate the dispense heads and to save the control parameters for standalone operation. External 24 V trigger-input synchronizes the VAEM with other systems. The controller’s dimensions are 3.6 x 3.9 x 1.1 inches (92 x 100 x 28 mm).

More Information

For more information, visit www.festo.ca.