ABB Infrared Camera on Hydrosat Satellite Delivers Strong Results and is Set to Enhance Water Scarcity Insights with Next Launch

July 21, 2025

ABB Infrared Camera on Hydrosat Satellite

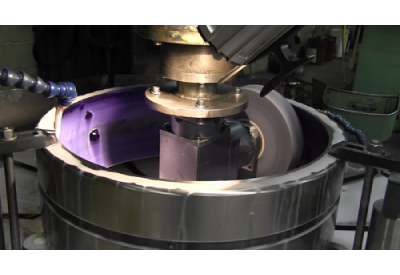

- In 2024, ABB’s infrared camera on board Hydrosat’s VanZyl-1 satellite sucessfully generated thermal imaging to support data to help governments and private sector stakeholders to address water stress in agriculture

- VanZyl-1 carries a unique calibration device that allows to precisely measure the soil temperature from 500 km above

- This summer, a second infrared camera sibling will equip Hydrosat’s VanZyl-2 satellite to provide high-accuracy temperature-sensing information

ABB is collaborating with Hydrosat, a company leveraging thermal satellite data and AI to address critical global challenges in food production, security, and natural resource management to develop and manufacture propriety infrared cameras that generate accurately calibrated surface temperature maps, helping to tackle water scarcity. Following the successful launch and in-orbit commissioning of Hydrosat’s VanZyl-1 satellite in 2024, the ABB infrared camera has started its operational mandate delivering high-accuracy temperature-sensing information 24/7. The strong performance of the payload observed in ABB’s laboratory before the launch has been confirmed also in orbit through in-depth analysis of Earth images by the Hydrosat team.

Building on the partnership success, a second infrared camera sibling will equip Hydrosat’s Vanzyl-2 satellite scheduled to launch during the summer of 2025.

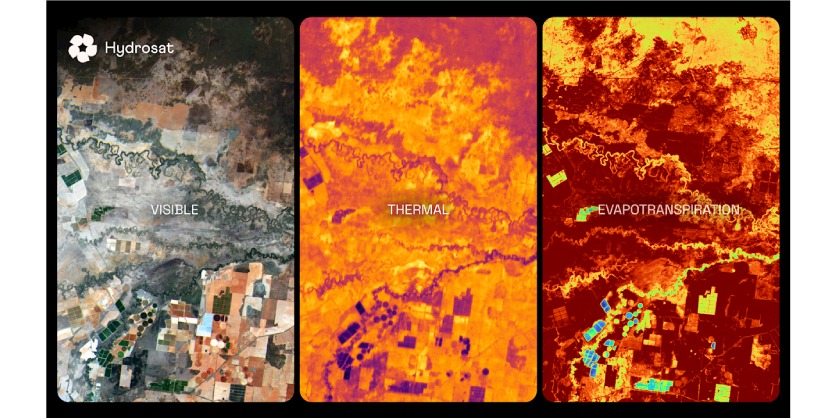

Hydrosat’s thermal data enables frequent and reliable access to sub-field scale insights – and can be used to monitor vegetation health, plan efficient irrigation, measure agricultural water productivity, and detect droughts. It can also be used to monitor heat output from industrial plants, detect ships and other heat sources at night, and pinpoint areas of recent deforestation related to new facility construction, among other commercial and security use cases.

The cameras work by measuring minute temperature variations of less than 0.1 degree Celsius across the Earth’s surface. When a field is under water stress, its temperature reacts more quickly and intensely to the sun illumination. The cameras thus probe soil humidity through the surface temperature proxy, similar to cameras measuring body temperature at airports. The satellite data can provide early warnings, helping to predict and prevent crop losses and poor yields before they occur.

While this method has been vetted with government-owned satellites in the past, these satellites provided either too coarse ground resolution from geostationary orbit or week-long revisits between observations from low Earth orbit, a latency incompatible with effective actionable measures. Continually imaging the Earth’s surface, Hydrosat’s VanZyl-1 satellite, and upcoming VanZyl-2, will set the stage for Hydrosat’s future constellation providing both high-resolution and high-frequency imagery anywhere on earth.

“ABB is committed to the conservation and smart use of water as an essential resource for sustainable societies,” said Jacques Mulbert, President of ABB’s Measurement & Analytics division. “Water touches every aspect of our lives in countless agricultural, industrial and domestic ways. For us, it is important to assist those managing this precious resource. With this project, ABB is advancing its goal of supporting sustainable development from space.”

“ABB has been a trusted partner, fully committed to advancing our mission of delivering daily, high-resolution thermal infrared data with global coverage,” says Scott Soenen, CTO of Hydrosat. “The ABB team’s expertise and the exceptional quality of the optical payload craftsmanship are critical to Hydrosat’s success in achieving this goal.”

ABB has been a leader in infrared sensing for more than 50 years. Some of the technologies used in the Hydrosat satellites have their roots in payloads delivered by ABB to the Canadian Space Agency for the MOPITT instrument flown on the NASA Terra satellite launched in 1999. The same technologies are also used to generate the weather forecast and study the Earth’s thermal regulation mechanism. ABB applies its vast expertise acquired in high-profile government space missions to the private space sector with a focus on optimizing performance.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps process, hybrid and maritime industries outrun – leaner and cleaner. go.abb/processautomation

More Information

Related Story

ABB Acquires Innovative Optical Sensor Company to Expand Smart Water Management Offering

ABB has announced that it has agreed to acquire Canadian company Real Tech, a leading supplier of innovative optical sensor technology that enables real-time water monitoring and testing. Through the acquisition, ABB will expand its strong presence in the water segment and complement its product portfolio with optical technology critical for smart water management. Financial terms of the transaction that is expected to close in Q1 2024 were not disclosed.