SEW-Eurodrive Showcases DriveRadar® IoT Suite

October 17, 2024

From Analysis to Defect Detection

Receiving critical condition alerts for your Gear Units is just one of the Smart Condition Monitoring features available with DriveRadar® IoT Suite.

Reliable Damage Detection. Example: Circumferential Gearing Damage

How does this help with maintenance?

For starters, if can measure 3,000,000 values per day, and DriveRadar® analyzes 34, 904 spectral images daily – equivalent to 225-man hours.

Smart Conditioning Monitoring 24/7

The Potential of Smart Maintenance

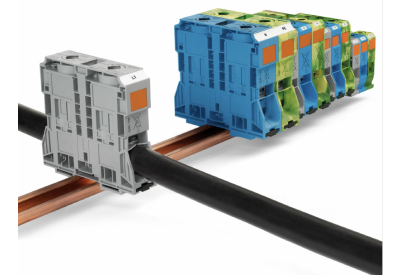

The DriveRadar® IoT suite package includes plug and play smart sensors, Edge processing, and intelligent data analysis to transform your static Gear units into sophisticated, self-learning, and self-diagnosing Gear Units.

The technology is designed to take the guesswork and even some of the thinking out of your maintenance tasks and allows you to view critical performance data right from your smart device.

Plan maintenance and repair activities predictively for your drives and avoid undesirable system failures.

Just some of the features:

- Early Detection of Faults

- Ability to Forecast Next Oil Change

- Predictive Maintenance

- Teach Mode

- Optimized Stockkeeping

- Faster Maintenance

- Reduced Downtime

- Receive Alerts if the Limit values change

- Receive Alerts in Temperature variances

- Create oil Error Handling protocols

- View graphical localization data when limit values are exceeded

- Error Handling with timestamp

- Recommendations for actions and appropriate services

- Calculated Warning and Fault detection

Why Condition Monitoring is Necessary

Smart Maintenance right on your Smart phone.

The Demand for Condition Monitoring is increasing tremendously and so is the need to monitor your Industrial gear units remotely. DriveRadar® IoT Suite for industrial gear units is your smart condition monitoring solution that connects you to your drive system anywhere. The benefit of DriveRadar® IoT Suite instills intelligent and machine learning concepts into your drive system and keeps them connected. The days of manual inspections and unplanned downtime can be eliminated with the DriveRadar® IoT Suite solution.

The Demand for Condition Monitoring is increasing tremendously.

SEW-Eurodrive surveyed 450 Industrial Companies:

- 83% had unplanned downtime in the past 3 years

- 70% had no scheduled maintenance planning

- 72% of respondents agreed failure prevention is top priority

- 87% of companies surveyed had unplanned downtime

Study: Vancson Bourne Basis 450 Industrial Companies 22.06.21

Interested in Condition Monitoring

Connect with SEW-Eurodrive’s Canadian DriveRadar ® Specialist.

Andy Chen Product Manager | DriveRadar® IoT | IG Units

Direct Line: 647.780.6536

Related Story

A Clear View Ahead for Industrial Gear Units. DriveRadar® from SEW-Eurodrive

Industrial gear units are used in many production activities worldwide, particularly in the heavy industries such as construction, mining, oil and gas, and industrial machinery. These applications require significant mechanical work from the gear units and demand mechanical products that can get the work done reliably. These industrial applications are expensive to operate, and insufficient equipment is not an option.