The New KRT 3C Contrast Sensor from Leuze. Put Into the Right Light

April 10, 2023

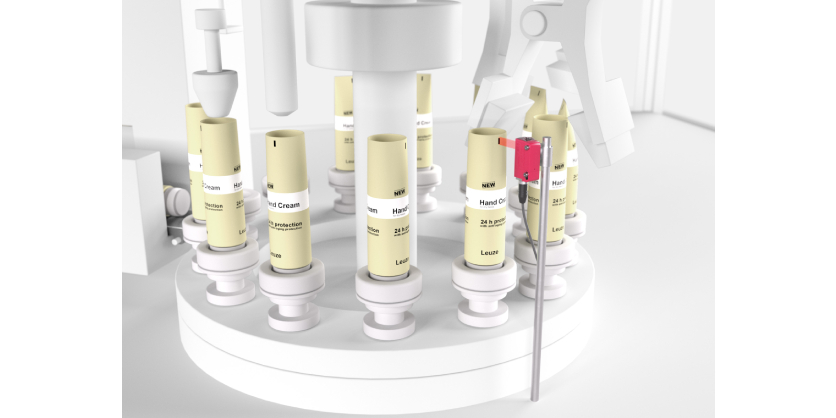

Many light types and a compact housing: The new KRT 3C contrast sensor from Leuze can be flexibly integrated into packaging processes thanks to its multicolor capability and small size.

With the KRT 3C contrast sensor, Leuze is presenting the smallest contrast sensor it has ever made for the packaging industry. Plant operators benefit from a compact device that can be used in many different ways: The KRT 3C detects reliably and position-accurately even if there are only small contrast differences and with glossy surfaces or highly reflective materials. This is made possible by the multicolor functionality: red, green, and blue light as well as white and laser red light will not allow any object or printed label to pass through unnoticed. This allows users to select the right light source for any material and contrast mark color for their packaging and labeling processes.

Tight space? No problem!

The KRT 3C detects contrasts very precisely and reliably and with a short response time of only 50 µs (laser: 125 µs) and minimal signal jitter. This helps to achieve optimal machine throughput. Advantage in small spaces: With its small dimensions of 11 x 32 x 17 mm, the sensor is designed for tight installation spaces. This means it can be fitted almost anywhere. Users can easily setup the KRT 3C via the integrated IO-Link interface. This also speeds up product format changeovers.

Really resilient

The housing is robust: It meets degrees of protection IP67 and IP69K. The KRT 3C is also ECOLAB-certified. So it can even handle aggressive cleaning agents.

More Information

Related Product

Leuze Sets New Standard for Compact Positioning System

The AMS 100i from Leuze is one of the smallest laser positioning systems available on the market. This makes it the perfect solution for tight installations spaces.