Orders Officially Open for “OMNIedge” IoT Service for Manufacturing’s AI Diagnostic Service (ADV) for Rotary Components

AI Predicts Rotary Component Abnormalities and Failures and Specifies Recommended Maintenance

March 24, 2023

THK is now offering the brand-new AI Diagnostic Service (ADV), following the rotary component solution for its “OMNIedge” IoT service for the manufacturing industry.

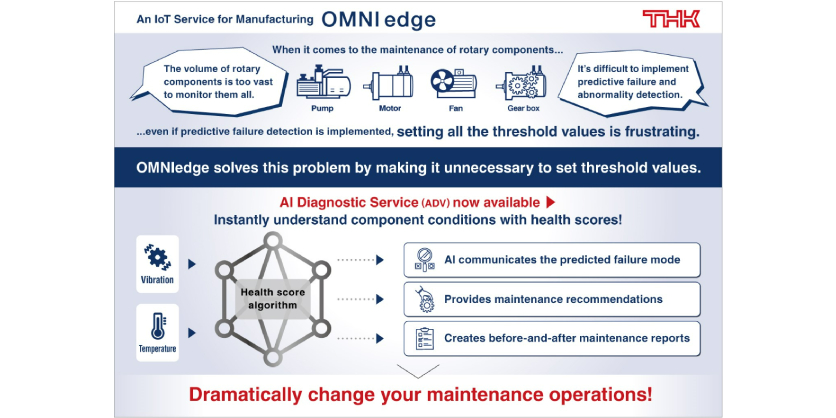

The maintenance of motors, pumps, fans, and other rotary components that are indispensable for process automation in factories involves a massive number of components even at a single factory, as well as daily patrols. In addition to that, the threshold settings for the sensors used to detect abnormalities are different for each rotary component, leading to the maintenance personnel in charge of setting such a vast number of parameters becoming overwhelmed and causing machines to be run without the appropriate threshold settings. To solve this, THK has expanded its rotary component solutions with the AI Diagnosis Service (ADV), which allows the status of rotary components to be understood with a health score.

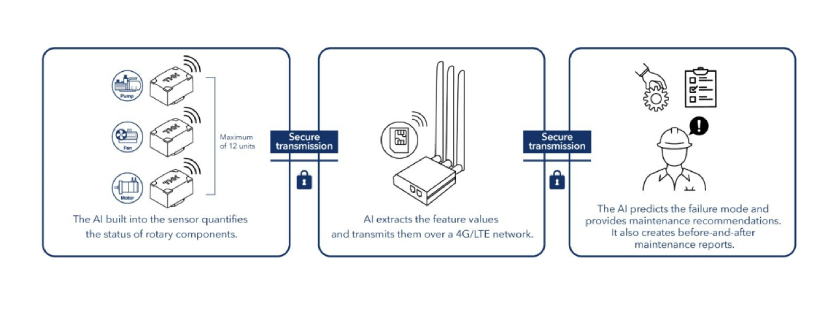

An algorithm that calculates health scores is utilized for the ADV, completely eliminating the traditional hassle of setting threshold values. Instead, health scores are calculated with the ADV based on vibration and temperature data to diagnose the condition of components. The ADV dramatically changes the maintenance of extensive quantities of rotary components by providing simple and easy-to-understand failure predictions and recommended maintenance. In addition to this, correlations between pre- and post-maintenance data changes can be created and presented in reports.

Synergistic effects can be achieved by combining the ADV with conventional remote monitoring functions, such as reducing the time required for patrols, identifying and implementing the optimal maintenance timing, and reducing the time required to prepare maintenance reports.

THK is working to further strengthen engagement with customers by not just providing sensors, but also working on a variety of services that utilize AI. Furthermore, THK also provides IoT solutions for reducing loss that occurs on the manufacturing floor and contributes to maximizing overall equipment efficiency (OEE).

AI Diagnostic Service (ADV) for Rotary Components System Structure

Special Features of the AI Diagnostic Service (ADV) for Rotary Components

Frustrating Threshold Value Settings Are Completely Unnecessary

Threshold values used to have to be set for each parameter, but this is now unnecessary due to AI-calculated health scores.

AI Predicts Expected Failure Modes and Specifies Recommended Maintenance

AI predicts and notifies the user of expected failure modes based on the collected vibration and temperature data trends and characteristics.

In addition, the recommended maintenance task that matches the failure mode is immediately presented to maintenance personnel.

Generates Before-and-After Maintenance Data Reports

Reports are provided showing data changes before and after maintenance, which makes them clear, easy to understand, and able to be used as evidence.

OMNIedge: An IoT Service for Manufacturing

OMNIedge is an IoT solution service that reduces loss that occurs on the manufacturing floor and contributes to maximizing overall equipment efficiency (OEE). This service is a package that combines the sensor and other hardware with a communication device along with the service itself as a set, making the service simple, secure, and available for a reasonable price.

- Phase 1: Predictive failure detection AI solution for linear motion components (available now)

Phase 2: Predictive failure detection AI solution for rotary components (AI Diagnostic Service (ADV) available now)

Phase 3: Tool monitoring AI solution (available now)

Launch of AI Diagnostic Service (ADV)

March 2023

More Information

Related Story

Automate, North America’s Largest Automation Trade Show, Returns To Detroit May 22-25

The leading automation showcase in North America, Automate, is back in Detroit May 22-25, 2023, with the latest in cutting-edge robotics, vision, artificial intelligence, motion control and more. Produced by the Association for Advancing Automation (A3), Automate delivers the latest innovations in manufacturing automation technology from more than 600 leading exhibitors. Each day also offers inspirational keynote sessions and theater presentations to help attendees find the best solutions for their unique business needs. Show registration is free.