Weleda Cradle Campus – Sustainability Meets Efficient Drive Technology

December 17, 2025

Weleda Cradle Campus – Sustainability Meets Efficient Drive Technology

In Schwäbisch Gmünd, Germany, Weleda has built a new logistics center: the Cradle Campus. This project combines ecological responsibility with technical precision – setting new standards in sustainable warehouse logistics.

Key features:

- A high-bay warehouse rack made of wood – instead of steel

- A facade constructed from clay excavated on-site – instead of concrete

- Use of renewable energy sources such as geothermal and solar – instead of fossil fuels, even for the stacker cranes

Technical equipment:

- 6 energy-efficient stacker cranes, including 5 single-mast and 1 double-mast unit

- Integrated energy storage technology

- 500 meters of pallet conveyor systems

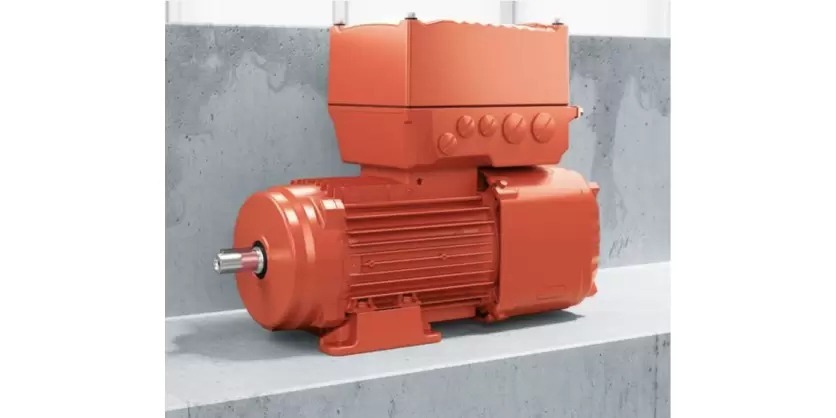

- 350 gearmotors

Energy efficiency:

- Peak power reduction by a factor of 7

- Up to 40% lower energy consumption

The Cradle Campus demonstrates:

- Sustainability is an integral part of modern warehouse logistics

- Technology can be both aesthetic and efficient

- Architecture and values can be meaningfully combined

More than a logistics center – Weleda is a forward-thinking concept with model character.

More Information

Related Story

SEW-Eurodrive Is Your Complete Source for Motion Control

SEW-Eurodrive specializes in custom, scalable drive solutions that focus on meeting the needs of customers today – and into the future. SEW-Eurodrive’s decentralized variable frequency drives combine power, communications, integration, and support all-in-one, saving you time and money. They have this and so much more to offer.

SEW-Eurodrive has set the trends and standards in drive engineering for years. Their universal concept of gearmotors, control systems, software, service, and extensive accessories are the cornerstone of many industrial motion systems. Dominique Salvail, Product Specialist, Factory Automation Solutions at SEW-Eurodrive, discusses how they have everything you need for your motion control application, and highlights how their decentralized VFDs can save you time and money.