Siemens Xcelerator: DMG MORI, Renishaw, and Siemens are Working as Innovation Partners and Expanding Digital Offerings for Machine Tools

September 11, 2024

- Siemens Xcelerator creates a powerful ecosystem of partners to accelerate digital transformation

- New scalable offerings for the end-to-end digital twin of the machine tool, control system, and workpiece

- New solution for tool condition monitoring enables traceability and closed-loop manufacturing

Siemens is consistently expanding its ecosystem for the machine tool industry. Together with its partners DMG MORI and Renishaw, the technology company is presenting new offerings as part of Siemens Xcelerator. With a focus on scalability and high flexibility, there are now even more intelligent machining applications for CNC users that seamlessly complement the Siemens solutions and deliver a high value-add based on them. The open digital business platform Siemens Xcelerator thus creates a powerful ecosystem of partners to jointly accelerate the digital transformation of the industry.

Renishaw: Quality monitoring of tools at the highest level

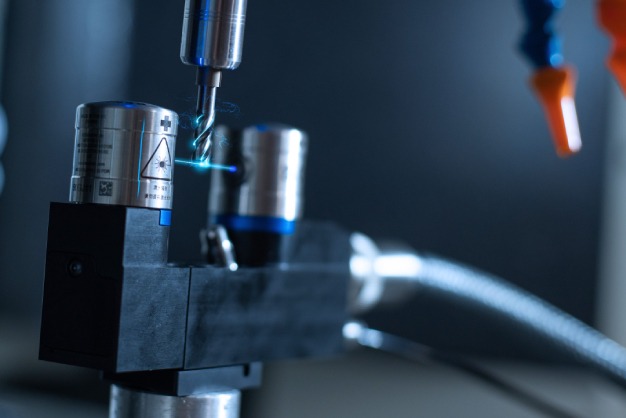

The Siemens Xcelerator offering from Renishaw consists of a solution for measuring and monitoring the condition of tools. The basic system is already offered by DMG MORI. The solution is based on a high-precision laser system for tool measurement from Renishaw and the edge-based analysis software Analyze MyWorkpiece /Monitor from Siemens. The condition monitoring solution enables the automatic validation of tool wear and the timely automatic replacement of worn tools. The solution also ensures that the manufacturing process is traceable thanks to data evaluation.

The fast tool inspection by optical scanning reduces manual intervention and therefore disruptions within the manufacturing process. The data-driven analysis approach ensures the traceability of the manufacturing process, which closes the loop in terms of quality assurance and production planning (closed-loop manufacturing). At AMB, the solution will be on display for the first time at DMG MORI (Hall 10) and at Renishaw (Hall 7, booth A11) on a DMU 60 eVo.

DMG MORI: Scalable offering for the end-to-end digital twin for machine tool machining at the Siemens Xcelerator Marketplace

The manufacturer of high-precision machine tools, DMG MORI, is expanding its offering for the end-to-end digital twin for machine tool machining on the Siemens Xcelerator Marketplace. Specific solutions for the digital twin of the control system, machine, and workpiece will be presented for a variety of applications. This makes it possible to optimize machining processes long before the real machine is put into operation. Based on the digital native CNC Sinumerik One, the portfolio includes a tailored digital twin for the user – regardless of the shop floor or CAM applications.

For example, machine operators on the shop floor can purchase a digital twin package that allows them to create a simple NC program on the PC and thus carry out a collision check without using the machine. A CAM user, on the other hand, can create sophisticated parts in a CAD environment and perform a quick initial validation of the program. With DMG MORI’s new, scalable digital twin offerings, customers can now individually determine the scope of the required simulation and purchase the corresponding packages.

The DMG MORI digital twin for machine tool machining helps to avoid programming errors that cause rejects and damage to the actual machine. It can ramp up production up to 40 percent faster, significantly reducing the energy consumption of the real machine. Even new processes can be set up digitally while the machine is in operation. It also helps to reduce unproductive machine times, such as test machining, by as much as 75 percent. This is because the testing and running-in of programs is transferred from the actual machine to the virtual world.

The DMG MORI machines DMU 50 3. Generation, CTX beta 450 TC, and NZ TRE rely on the Sinumerik One with its performance and state-of-the-art shop floor programming. At the trade fair, visitors can experience the machines and their end-to-end digital twin first-hand at the DMG MORI booth in Hall 10.

The Siemens Xcelerator offering from Renishaw consists of a solution for measuring and monitoring the condition of tools.

With the new, scalable digital twin offerings from DMG MORI, customers can now individually determine the scope of the required simulation and purchase the corresponding packages.

Related Story

Siemens to Demonstrate the Path to “Empowering The Digital Machine Shop” at IMTS 2024, Booth 133249

At the upcoming IMTS 2024 in Chicago, September 9–14, Siemens will present its extensive machine tool CNC portfolio and digitalization software technology, highlighted by the digital native SINUMERIK ONE control platform for machining applications. Also, using a sports theme of “Speed, Agility and Endurance,” aimed at the machine shop on its path to digitalization, Siemens will introduce MACHINUM to the North American market.