Rockwell Automation Delivers Reliable Decoding at the Speed You Need

January 28, 2021

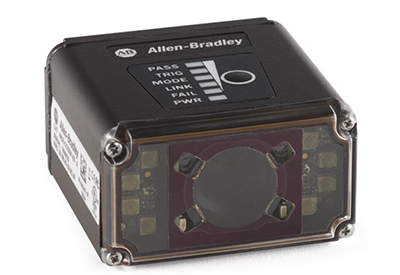

The new Allen-Bradley 48CR Code Reader from Rockwell Automation delivers 1D, 2D and Direct Part Marked (DPM) code reading – including barcodes and QR Codes – in a small package. This rugged code reader is designed for easy, cost-effective integration into the Connected Enterprise. Simple integration delivers data from the plant floor directly into a control system to help minimize downtime and increase productivity.

With powerful scanning and flexible programming, the 48CR streamlines code reading processes across several applications, especially in automotive, packaging, material handling, pharmaceutical, and food and beverage industries.

- – Start scanning fast: Get right to work with simple configuration. Ethernet/IP supported 48CR offers multiple setup options – fitting seamlessly into existing Rockwell Automation systems with the Studio 5000 Add-on Profile or into any other system using embedded WebConnect software.

- – Increase capabilities: With the latest decoding algorithm technology, the 48CR can successfully read damaged and incomplete symbols – even with poor prints, scratches or other obstructions – without slowing down the scanning process.

- – Save on maintenance, limit downtime: This intuitive device does not require any additional software or extensive training for operators. Because the configurations can be saved remotely, personnel on the floor can even swap out a code reader without extended downtime to reconfigure or wait for a specialized technician.

The 48CR is available in a standard model (0.3 MP resolution, fixed focus) and an advanced model (1.2 MP resolution, autofocus). For reliable decoding at the speed you need, the 48CR has speeds up to 60 fps for fixed focus and 42 fps for autofocus.