Olis Launches $499 Diagnostic Tool That Runs on Any Android Device

May 1, 2025

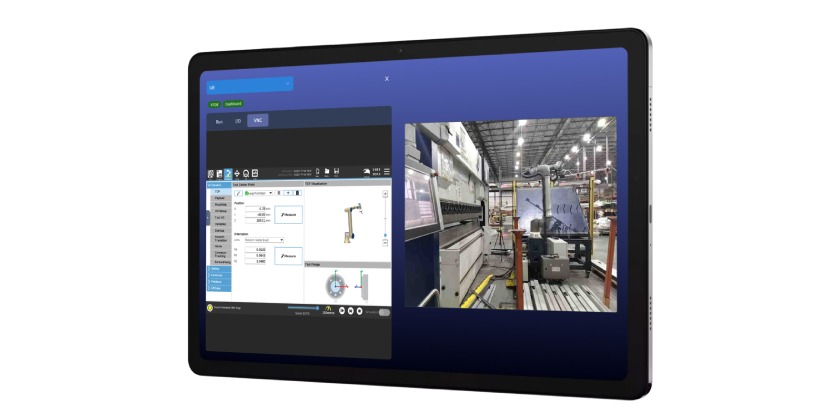

At Automate 2025, Olis will launch a remote automation monitoring, diagnostic and error recovery app that turns Android smartphones and tablets into gateways for any automation cell without the need for additional hardware.

Automate attendees entering Olis Robotics’ booth #3748 in Detroit, May 12-15, will be the first to experience a future in which their mobile device becomes the gateway to remotely managing an automation cell.

“We’re incredibly excited to show visitors how easy it is now to safely, inexpensively and securely connect their mobile phone or tablet directly to an industrial controller (PLC) without any additional hardware required,” says CEO of Olis Robotics, Fredrik Ryden.

By connecting their mobile device to a PLC through the new Olis app, attendees can experience how easy it is to get going. They will also be able to remotely control a robot arm and view live video of a remote robot with PLC/telemetry data overlaid, enabling users to diagnose automation issues instantly from anywhere in the world.

Complete picture of what went wrong

The Olis app synchronizes real-time video with system logs, providing a complete picture of what went wrong. “With remote access to the automation cell, engineers can resolve problems faster and keep production running smoothly without unnecessary guess work and travel,” says Ryden.

Full set-up takes less than five minutes-including a simple online purchase-making it an efficient retrofit for legacy automation systems. Users simply download the Olis app onto an Android tablet or phone and connect an ethernet connection to the controller. From there, they can configure IP addresses and start collecting diagnostic data.

In addition to receiving synchronized telemetry and video in parallel, engineers can set up alerts regarding irregular activity before it escalates into a costly hard stop. The app also supports screen-sharing functionality, enabling troubleshooting teams to collaborate in real-time.

Mid Atlantic Machinery among early adopters

Mid Atlantic Machinery Automation is one of the companies already benefiting from using the app. “Deploying the Olis app on an Android tablet is the easiest way to add diagnostics capabilities to our machines,” says Josh Mayse, VP and Co-founder of MidAtlantic. “This helps our service team manage our rapidly growing install base. At MidAtlantic, the app is being used in press brake tending applications, where it continuously monitors performance and operational data. What’s more, customers no longer need to invest in industrial PCs—they can now access the entire automation cell directly through a mobile device, making setup and support significantly more streamlined.”

For customized workflows, users can set up special tags and filters to customize Olis to their operational needs enabling system integrators to assess situations remotely, minimize travel and troubleshoot more efficiently.

“Instead of reactive maintenance and lengthy troubleshooting cycles, the Olis app enables businesses to take a proactive, predictive approach to maintenance and tackle troubleshooting issues quickly, ensuring minimal disruption to production following unexpected downtime,“ says the Olis CEO.

More Information

Related Story

Olis Robotics Launches New PLC Capabilities at IMTS

Olis Robotics will launch what they say is the world’s most comprehensive remote diagnostics solution for industrial automation cells at IMTS 2024 in Chicago, September 9-14, following the addition of powerful new PLC capabilities to its solution.

Olis provides video and telemetry-based diagnostics for industrial cells, enabling technicians to diagnose the root cause of downtime events, such as a robot failure. Immediate access to diagnostic data enables the robotic cell to be debugged quickly and remotely, slashing manufacturer downtime while empowering integrators to take on more business.