The Next Multi-Touch Panel Generation

High-quality industrial displays with multi-finger touch function

September 17, 2025

Efficiency in operation: The Next multi-touch panel generation

The Next multi-touch panel series is advanced and cost-optimized, and further expands the diversity of Beckhoff’s broad portfolio. As usual, this generation of control panels and panel PCs offers convenient operation with advanced multi-touch technology, a high-quality look and feel, and a wide choice of formats and options.

For optimized operating concepts

- contemporary, elegant design and high-quality workmanship

- high-quality industrial displays with multi-finger touch function

- high-end panels for demanding human-machine interface and control tasks

- developed and manufactured in-house, entirely in Germany

- long-term availability with long-term servicing and high durability

- 7 to 24-inch displays in various formats

- various types of connection technology for control panels

- a wide range of CPU performance classes for the panel PCs

- available as built-in and mounting arm versions

- IP20 and IP65-protected versions for any environment

- for direct mounting on a VESA monitor mount by the customer

- can be directly mounted on a 48 mm round tube with a mounting arm

- a variety of accessories and mechanical extensions

- EtherCAT communication (FSoE) at the touch of a button

Next multi-touch panel generation in a smart design

The main draw for this class of panels is its attractive pricing. Beckhoff has kept the price low while maintaining a consistently high level of quality by effectively managing manufacturing costs. With the next multi-touch panel generation, Beckhoff is now bringing out a smart panel design, based on over 25 years of successful in-house panel production and 12 years of expertise in multi-touch design. With its revised electronics concept and standardized connection solution for electronics and mechanics, the device platform maintains its future-proof technological lead and builds on it while optimizing costs.

Advantages of the next multi-touch panel generation

- future-proof panel platform due to integration of the latest standards

- easy cost optimization without any changes to the system design

- elegant and functional panels are a calling card for the system

- individual adaptation to areas of application or customer requirements

- intuitive and safe operation via an industry-standard HMI

- tried-and-tested touch technology with anti-glare and anti-ghosting effect

- reliable investment protection for long-standing industrial plants

Product status: product announcement | estimated market release 1st quarter 2026

More Information

CP49xx | Next multi-touch built-in Control Panel: Control panels for installation in the front of a control cabinet in display sizes from 7 to 23.8 inches

CP59xx | Next multi-touch built-in Control Panel: Control panels for mounting arm installation in display sizes from 25.6 to 23.8 inches

Related Product

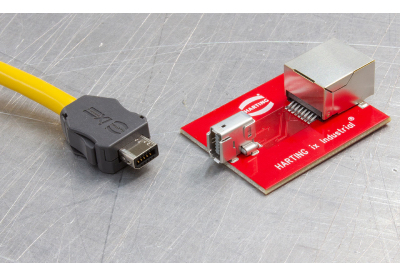

Beckhoff Future-Proofs Hybrid Connectors in Industrial Cable Offering

Beckhoff’s proven hybrid connectors, part of the company’s One Cable Automation (OCA) solution, are receiving a major update to better support distributed automation well into the future. Beyond the design advantages of consistent modularization with a uniform data core, these connectors now comply with the upcoming IEC 61076-2-118 standard, enabling a seamless transition in advance of the rollout.