MultiTask Photoelectric Sensors Roller Sensor Bar from SICK

May 24, 2022

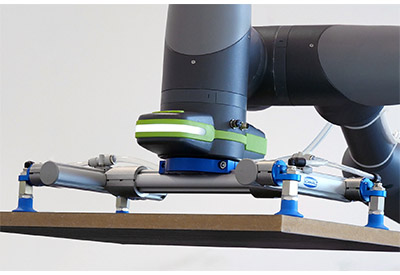

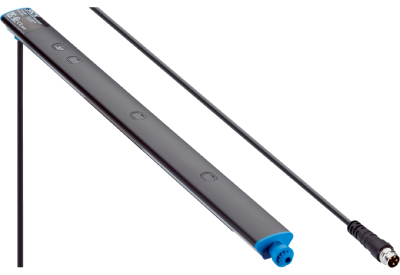

The Roller Sensor Bar conveyor sensor is designed to be mounted between rollers and is an elegant, simple solution for reliable detection of objects with irregular leading edges. Sensing performance is optimized through the ability to configure length and beam spacing to the mm.

By mounting the Roller Sensor Bar between the rollers, object catch points can be removed thereby decreasing conveyor downtime due to jams. The spring-loaded assembly of the Roller Sensor Bar, which can be mounted in the factory rather than in the field, decreases installation costs by more than half. Commissioning costs are reduced by eliminating the need to teach and align the sensor.

- •Precise detection of leading edges

- •Outstanding ambient light immunity

- •Easy installation

- •Housing length: 200 mm to 1,200 mm (7.87″ – 47.24″)

- •Beam separation: 50 mm to 200 mm (1.97″ – 7.87″)

- •Number of sensing points: 2 to 8

- •IO-link allows for individual beam break information for product alignment

Your Benefits

- •Reduce conveyor downtime due to false switchings on background-objects

- •Optimize sensor performance by configuring beam spacing to the mm

- •Increase detection area across the entire conveyor bed by removing blind zones on the near and far side of the conveyor

- •IO-Link provides individual beam break information which can be used for product alignment.

- •Significantly decrease installation costs with a tool-free installation using a spring-loaded end cap

- •Eliminate the need for sensor alignment and teaching with factory preset sensing range

![]()

![]()

![]()

To learn more about the Roller Sensor Bar conveyor sensor from SICK, download the Product Page by clicking here or visit the Product Page by clicking here