Introducing Our Strongest Mobile Robot, the New HD-1500 by Omron

November 29, 2021

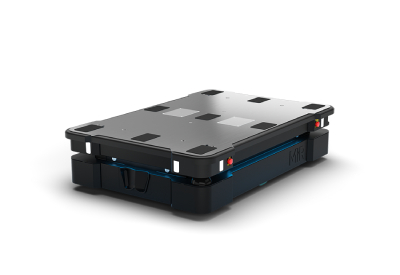

Introducing Omron’s strongest mobile robot. With a 1,500kg payload capacity, the new HD-1500 autonomously loads and transports the heaviest of objects. This ultra-strong mobile robot features studier metal skins that withstand heavier impacts and more demanding tasks. This powerful solution based on proven LD Series technology will reduce forklift usage and get more done with less equipment. Omron’s mobile robot offering is expanding by the year to meet your specific needs with easy deployment.

The HD-1500 features an integrated on-board user-accessible Omron PLC, Dynamic Safety Zones, superior navigation performance and rapid battery re-charge and capacity in under 40 minutes.

Greatest payload capacity yet

Now you can automate the transport of pallet-size loads, engine blocks, and other items up to 1,500kg and reduce the risk of injury by replacing tasks traditionally completed with forklifts.

Easy and intuitive customization

We give customers the most options when it comes to customizing a mobile solution, and our industry-leading Fleet Manager solution lets you control a diverse fleet with one system.

Built-in safety features

The HD-1500 includes built-in 360° safety lasers, emergency stops, audio warnings, LED visual warnings, safety scanning lasers and obstacle-avoidance technology to protect people nearby.

Same proven technology

The newest addition to our mobile robot lineup employs the powerful self-navigating and mapping technology that’s already being used in our popular LD Series mobile robots.

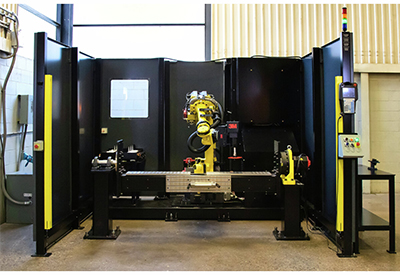

A fully customizable and safe addition to the factory floor

The HD-1500 can be used to create a solution that best meets the needs of every manufacturer, and can be easily customized with HAPS, LiDAR and other accessories that improve performance.

Designed to meet the industry’s latest safety requirements, OMron’s mobile robots interact with people to promote a collaborative, safe working environment.

To learn more about the new HD-1500 mobile robot click here