IDEC ez-Wheel Safety Wheel Drive Simplifies Safe Payload Mobility

March 27, 2025

Safety Wheel Drive is an innovative all-in-one solution combining a wheel, gearbox, motor, safety encoder, and safety drive to streamline the integration of powered motion into any type of industrial mobile platform.

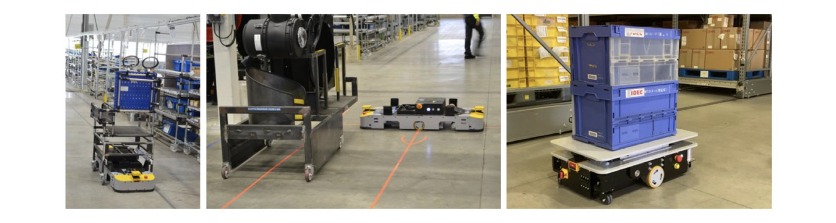

IDEC Corporation is expanding its ez-Wheel® product family with the new SWD® Safety Wheel Drive. The increasing demand for automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) has created a need for the SWD, which provides a streamlined way for designers to incorporate efficient, reliable, and safe motion control into their equipment and systems.

Fewer components, greater capability

Traditional drive systems require designers to qualify, integrate, and test a combination of wheels, gearboxes, motors, encoders, controllers, and power systems. External batteries and wiring increase installation costs. The SWD overcomes these requirements with options combining all these elements into a single, extremely compact, and maintenance-free solution, reducing component count by up to 50%. There is no other equivalent self-contained solution available in the U.S.

With a modular architecture providing the freedom to flexibly scale as needed, the SWD reduces engineering time and simplifies the certification process. Designers can confidently select the SWD for their application and focus their efforts on higher-level control and human-machine interface requirements.

Powerful performance

The SWD is available in a light/medium SWD 125 model or a heavy-duty SWD 150 model both with a load supporting cast iron frame. A robust shockproof housing, rated IP66 to protect its internal electronics, ensures the SWD is adaptable for a wide range of applications.

For each model, two gear ratios are available, each with or without a parking brake. Payload ratings are:

- SWD 125: supports a 250kg vertical load and targets applications up to a ton

- SWD 150: supports a 700kg vertical load and targets applications above a ton

Each SWD is connectorized for 24VDC power, safe input/output (I/O) signals, CANopen communication, USB, Ethernet (future), and brake functions. This provides quick and serviceable plug-and-cord connections between the SWD and other external automation components. LEDs on-board the SWD provide a clear indication of CAN and motor status.

Superior safety

A focus on safety further distinguishes the SWD, which ensures application’s compliance with the ISO 3691-4 international standard for AGV/AMR safety. When integrated with other safety devices, such as IDEC SE2L laser scanners or bumper/edge switches, the SWD can provide Safe Brake Control (SBC), Safely Limited Speed (SLS), and Safe Direction (SDI) with a SIL2/PLd rating. A SIL3/PLe safe motor disconnection (STO) is also integrated.

Getting started

A pre-packaged development/starter kit is available to accelerate design and reduce implementation efforts. This kit includes a pair of SWD Core, an SE2L safety laser scanner, a 24VDC battery pack with charger, an IPC controller, a central interconnection box, a pair of emergency stop buttons, and a manual controller. Developers can use this up-and-running kit (mounted, cabled and configured) to help them integrate the SWD with a PC, PLC, safety sensors, and other wired and wireless automation components. End users, systems integrators, original equipment machine builders, and firms that assemble AGV/AMRs from modular components will find significant advantages by adopting the SWD as a plug-and-play drive solution.

The IDEC ez-Wheel product family across its SWD range reduces development time, while providing sophisticated and smooth powered motion, and it is ideal for AGV/AMRs, mobile robots, and other similar platforms used throughout a wide variety of industries. As with all its products, IDEC offers free tech support for the SWD, with no service or support contract required. For complete specifications or additional information, please contact IDEC Corporation at 800-262-IDEC (4332), or visit us online at https://us.idec.com/idec-us/en/USD/Safety-Wheel-Drive/Safety-Wheel-Drive/c/SWD_Series .

About IDEC:

IDEC Corporation is a global supplier that has provided innovative and reliable industrial automation and control products since 1945. Covering a broad range of market needs, these feature-rich and value-driven products include PLCs, human machine interfaces (HMIs), safety products and other industrial automation components. By delivering world-class products backed by personalized service and highly-rated technical support, IDEC enables design engineers to create lean, cost-effective and safe solutions to optimize their automation applications. With the acquisition of ez-Wheel, as well as the acquisition of APEM, one of the world’s leading manufacturers of operator interface panels and related components, IDEC continues to enhance our customers’ ability to create high-quality solutions.

More Information

For additional information, visit www.IDEC.com/usa