Festo Adding Production of Multilayer Manifolds for Medical Technology, Lab Automation

June 11, 2024

Festo is expanding its portfolio to include manufacturing multilayer manifolds

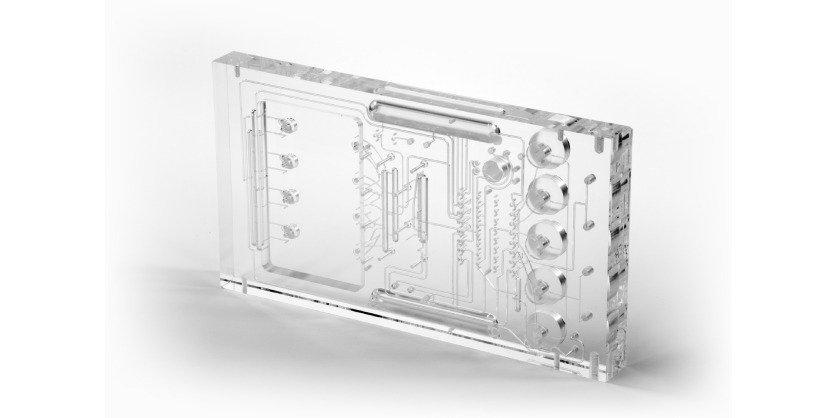

Festo is expanding its portfolio to include manufacturing multilayer manifolds made of plastic to be able to offer manufacturers of medical and laboratory equipment complete microfluidic solutions from a single source.

Festo is taking over the production systems and processes for manufacturing these bonded manifolds from Carville, a British-based leader in this field. Carville will cease operations in mid-2024 as the owner is retiring and has not found a successor for the business. This will enable Festo to produce these complex manifolds according to the specific requirements of customers in the medical technology and laboratory automation sectors.

Multilayer manifolds are key products for the connection of fluidic components and the distribution of liquids and gases in fluidic systems. Compared to conventional tubed or machined systems, they offer the possibility of significantly increasing integration density and process reliability.

The highly specialized HADB technology (High Accuracy Diffusion Bonding) used here enables the precise production of manifolds made of acrylic and Ultem and, thanks to the high geometric precision, also allows microfluidic applications to be implemented intelligently.

HADB technology leads to competitive advantages, particularly in medical technology, diagnostics and the life sciences. In combination with the media-separated valves of the VYKA, VYKB and VYKC series, Festo will be able to offer complete microfluidic solutions from a single source.

Festo at a glance

Festo, the world’s leading supplier of automation technology and technical education, is deploying its products and services to meet the challenges of digitization and smart production. Founded in 1925, the family-owned company based in Esslingen, Germany supports a wide range of needs for advanced solutions in factory and process automation. In Canada, Festo has been supporting Canadian industry for almost 50 years, continuously elevating the state of manufacturing in this country with innovative products, optimized motion control solutions and unrivalled support.

Globally, some 300,000 customers put their trust in the company’s pneumatic and electric drive products and technology. In addition, Festo Didactic provides state-of-the-art training equipment and educational programs for industrial companies and educational institutions – about 56,000 customers worldwide. The Festo Group registered sales of €3.65 billion in the 2023 financial year and is represented worldwide at 250 locations with about 20,600 employees. About 7.7% of its annual turnover is invested in research and development.

More Information

Related Story

Festo’s Innovative Solutions for Laboratory Automation

The healthcare industry encounters numerous challenges in meeting demand and time-to-market for new products and innovations. Festo’s Life Science division offers innovative solutions for laboratory automation and medical technology companies to address these challenges. As a leading supplier of pneumatic and electrical automation products, the company supports life science companies such as ATS Life Sciences Systems with customized solutions that meet their customers’ demanding challenges.