Festo Advances High-Throughput Automated Pipetting with Speedy Closed-Loop Control

March 8, 2023

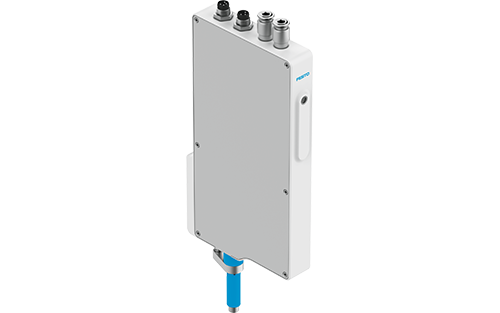

Festo introduces the DHOP closed-loop pipette head for high-speed robotic pipetting applications requiring consistent volumes over a wide range of liquid viscosities. The DHOP pipette head provides the utmost in automation flexibility, speed, and feedback when devices handle many liquids. (SLAS, Feb. 25 – March 1, San Diego Convention Center, Booth #837)

Based on Festo’s innovative air-over-liquid fluid handling system, the DHOP pipette ensures that aspiration and dispensing are independent of viscosity. By measuring the pressure change when a liquid is aspirated or dispensed, the device is able to calibrate for different viscosities without user input. Faster changeover between liquids leads to higher throughput and maximum device utilization.

Applications for this closed-loop pipette head include pre-analytical sample preparation of patient samples, where liquid properties of the sample might change patient to patient. Festo Life Science personnel work with OEMs from inception to implementation, which brings products to market faster, with less engineering overhead and risk.

The DHOP closed-loop pipette head seamlessly integrates with Festo’s world-class mechatronic systems, including the new EXCL multi-axis gantry that lowers engineering, acquisition, and assembly costs while increasing machine capabilities.

In the air-over-pressure system, liquid aspirates into the disposable tip using vacuum and dispenses using pressure. The DHOP is compatible with the new PGVA-2 pressure and vacuum generator, a compact solution for laboratories without a central compressed air supply. A single PGVA-2, which allows the pressure supply to be centralized, can operate up to 8 DHOP. Festo designs its components, such as the EXCL, PGVA-2, pipettes, and other components, to interoperate, which reduces engineering and lowers risk.

The DHOP is compatible with the just introduced DHAP disposable pipette tips. DHAP disposable tips prevent contamination when handling different liquids because a new tip is automatically used for every pipetting process. Picking, sensing, and ejecting – the complete automated handling process for disposable tips – is integrated into the DHOP pipette-head system.

DHOP provides the control system with feedback on every pipetted volume for traceability and quality assurance. The internal controller adjusts the target volume and returns the achieved value to the controller. Pressure-based liquid level detection prior to aspiration ensures maximum precision. Any foam on the surface is ignored in level detection. The liquid velocity is adjusted by changing the pressure on the system; this allows for soft dispensing with sensitive media or better droplet separation with small volumes.

Festo DHOP advantages include:

- A single product for the complete volume range

- Maximum precision through closed-loop control

- Intelligent functions such as liquid level detection and multiple dispensing

- Complete handling process for the disposable tips, from detecting tip attachment to automatic ejection

- Easy commissioning with integrated WebGUI

- Easy integration with Festo mechatronic systems for a complete microfluidics solution

Specifications include:

- Pipetting volume 1…1000 µl

- Viscosity range 0.1…40mPas

- Pipette tip volume 20, 300, 1000 µl

- 18 mm grid for microwell plates

- Communications Ethernet/Modbus, RS232, and can be operated manually via web interface

For more information on Festo Life Science solutions – dispensing liquids, controlling gases, and handling and gripping vials ‒ email life.sciences.nam@festo.com and visit Festo Laboratory Automation. Visit www.festo.us for the full range of products.

Related Story

Fast MDx and Festo: Saving Lives Worldwide with Low-Cost Molecular Diagnostic Tests

Fast MDx is the first fully automated, high-throughput, near-patient testing system. It will be launched in May 2023 with a multiplexed, CE-IVDr-approved test for the most common respiratory pathogens, influenza A, influenza B, RSV A, RSV B and Covid-19. Further assays will be added to the test menu in the near future. The test platform is usually set up close to the patient in hospitals, clinics or doctors’ surgeries. This saves time, cost and the need to transport samples. “As a result, infected people receive faster personalised treatment.” explains Richard Lewis, founder and CEO of Fast MDx.