Festo AI-Powered Pneumatic Cylinder Monitoring Cuts Machine Downtime, Transforming Maintenance from Reactive to Predictive

October 3, 2025

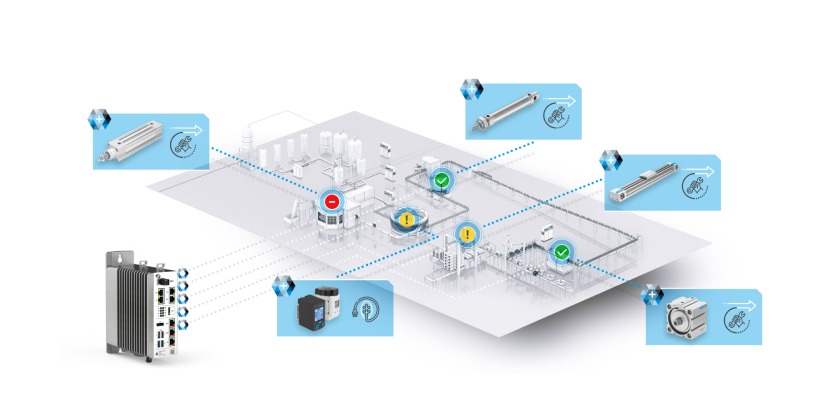

Festo introduces its AI-enabled monitoring and predictive maintenance system Festo AX Motion Insights Pneumatic. AX Motion Insights Pneumatic is a cost-effective, easy-to-use solution for preventing costly unscheduled machine downtime through its monitoring of pneumatic cylinders for wear and anomalies. This AI-based industrial app ensures operations are more reliable, efficient, and ultimately more profitable.

The system uses AI to detect anomalies in the behaviour of pneumatic drives and cylinders without the need for additional sensors. It provides a “Health Score” as a “risk of failure” indicator for each cylinder. Connectivity is achieved via a PLC function block. The system is compatible with actuators from different manufacturers and has specific connectivity details for Siemens, Rockwell, and Beckhoff controllers.

Motion Insights Pneumatic enables maintenance teams to schedule tasks in advance, significantly reducing the risk of unexpected downtime. The platform offers the flexibility of on-premises computing, giving end users full control over their data and deployment. This is an open system and works with both Festo and third-party components. The AX platform features ease of use and seamless integration, opening the door for customers to embrace without worry today’s AI, data-driven solutions, and digital transformation.

A critical element of Motion Insights Pneumatic is its integration with Festo’s Smartenance maintenance management system. Motion Insights Pneumatic works in tandem with Smartenance; the insights app identifies when maintenance is needed, and Smartenance manages the resulting tasks. The integration of the two creates a cohesive, end-to-end workflow that ensures predictive insights are not just seen but also efficiently acted upon.

Motion Insights Pneumatic is easy to set up and use. The “plug-and-play” aspect of this app, combined with its user-friendly interface and standardized AI models, makes the technology more accessible than otherwise possible. This is beneficial for original equipment manufacturers (OEMs) and end-use companies that are just beginning their digital journey, as it lowers the barrier to entry and brings the benefits of AI without requiring deep data-science expertise. OEMs and end users simply download the app, install it, and integrate it themselves. It’s that easy.

Festo AX Motion Insights Pneumatic joins the Festo AX Motion Insights Electric app, which focuses on electric components, and Festo AX Data Access, which makes operation technology (OT) data available for information technology (IT) analysis. These apps can be used singly or in combination. CODI Manufacturing, Littleton, Colorado, recently installed all three on its new, compact gantry palletizer to give customers the ultimate in uptime and insights into operational efficiency.

The apps can be deployed on-premises using standard hardware and container technology such as Docker. Containerization allows the apps to be deployed flexibly on various computing environments, including industrial PCs, virtual machines, servers, and edge devices. Insights Electric and Pneumatic are purchased on a subscription basis while “time-limited” options (3 and 5 years) will be released at the end of 2025. Data Access is purchased under a perpetual license.

Through Festo App World, customers can select a license package based on the number of cylinders they want to monitor. Unlike competitors that might offer a single software tool, Festo AX apps are a seamless part of a complete one-stop-shop automation solution, including its electrical and pneumatic components. This simplifies integration and offers a single point of contact for support.

About Festo

Festo, the world’s leading supplier of automation technology and technical education, is deploying its products and services to meet the challenges of digitization and smart production. Founded in 1925, the family-owned company based in Esslingen, Germany supports a wide range of needs for advanced solutions in factory and process automation. In Canada, Festo has been supporting Canadian industry for 50 years, continuously elevating the state of manufacturing in this country with innovative products, optimized motion control solutions and unrivalled support.

Globally, some 300,000 customers put their trust in the company’s pneumatic and electric drive products and technology. In addition, Festo Didactic provides state-of-the-art training equipment and educational programs for industrial companies and educational institutions – about 56,000 customers worldwide. The Festo Group registered sales of €3.45 billion in the 2024 financial year and is represented worldwide at 250 locations with about 20,600 employees. About 8.8% of its annual turnover is invested in research and development.

More Information

Related Story

Festo: Optimistic Start for 100th Anniversary Year

The Festo Group achieved a positive result in the financial year 2024, on par with the previous year, as announced by the Chairman of the Management Board, Thomas Böck, at a press conference held during the Hannover Messe. The innovation leader significantly expanded its portfolio in electric and pneumatic automation, particularly in the areas of control technology and digital solutions, software and AI. The company will continue to invest heavily in innovations in the future. This enables Festo, as a partner in motion, to offer integrated and seamless drive technologies from a single source –– complemented by a comprehensive range of technical training and education solutions.