Endress+Hauser Enhances its Go-To Flowmeter for Food+Beverage and Life Sciences

November 7, 2023

Promag H flowmeter provides temperature, flow and conductivity measurement in one device

Endress+Hauser is adding more innovations to its feature-rich Proline Promag H 300/500 series electromagnetic flowmeters for hygienic operations, endowing them with more capability to assure process integrity and maximize production uptime. Promag H is the go-to series for the food and beverage and life sciences sectors.

Promag H provides temperature, flow and conductivity measurement in one device. It’s a best seller for that versatility and for its rugged design, which enables it to resist the rigours of Cleaning In Place (CIP) cycles like elevated temperatures of aggressive chemicals, and strong vibration from the turbulent flows required for thorough cleaning.

The latest innovations concern both sensor and transmitter technology.

- Incorporating the Heartbeat Technology build-up index allows users to monitor potentially disruptive build-up in the measuring tube so they can schedule preventive maintenance when convenient or determine optimum CIP intervals.

- Adding the HBSI (Heartbeat Technology Sensor Integrity) parameter detects potential changes or defects in the flowmeter’s magnetic system.

- A new conductivity calibration option provides an additional measurement parameter to improve process efficiency. It serves for process control, product as well as water monitoring or leakage detection under varying conductivities, thereby preventing unexpected downtime.

Conductivity measurement can show whether a line is empty or full, and the kind and concentration of fluid in the pipe. During CIP cycles, Promag H’s triple measurement capability informs the operator of the concentration and temperature of the cleaning agent and its velocity, and ultimately, when conductivity reaches the appropriately low level, that the final rinse cycle has flushed all cleaning agent from the line.

Promag H’s patented technology measures conductivity productivity with a repeatability of up to ±1% and an accuracy of up to ±5%. The conductivity calibration option assures the accuracy and repeatability of the measurement. Temperature is also important variable in the food and Life Sci industries. Promag H has an internal PT1000 RTD with an accuracy of ±3 degrees. Utilizing these options is an excellent way to have a redundant measurement to the measurement devices already installed in their CIP systems.

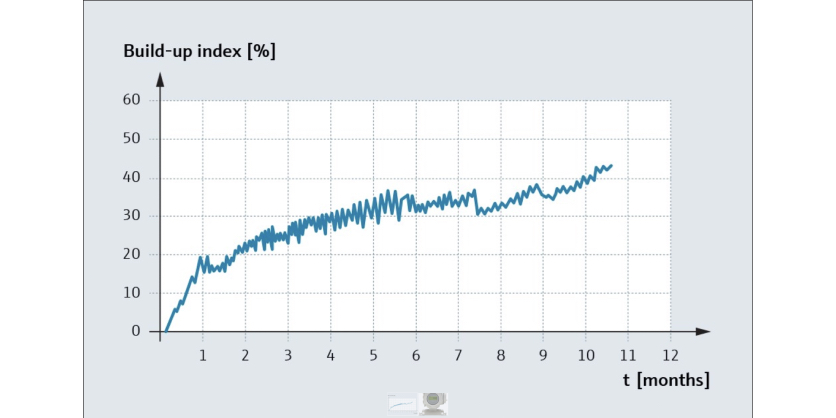

Build-up on an electromagnetic flowmeter sensor often is indicative of a growing problem in the measuring tube that could, once it reaches a certain point, degrade system performance and potentially damage process components. With its signal data, Heartbeat Technology creates a build-up index graphing the presence and progression of build-up over a period of months so that operators can make a real-time assessment of when the issue is significant enough to warrant a maintenance intervention.

Last but not least, changes in the electromagnetic field strength of Promag H flowmeters can be monitored continuously with the HSBI parameter, detecting, and quantifying potential magnetic interferences and mechanical defects in the magnetic system of the flowmeter. This leads to even higher confidence in the resulting flow measurement value.

More Information

Related Product

Heartbeat Technology – Taking the Pulse of Your Measurement from Endress+Hauser

Endress+Hauser has incorporated its market leading Heartbeat Technology in many of its newest measurement and monitoring devices, like the Prosonic Flow W 400 , Proline 10 and Promag W 800 liquid flowmeters and t-mass F/I 300/500 thermal flowmeter.