Akribis Introduces Magnetic Springs For Gravity Compensation Applications

December 22, 2023

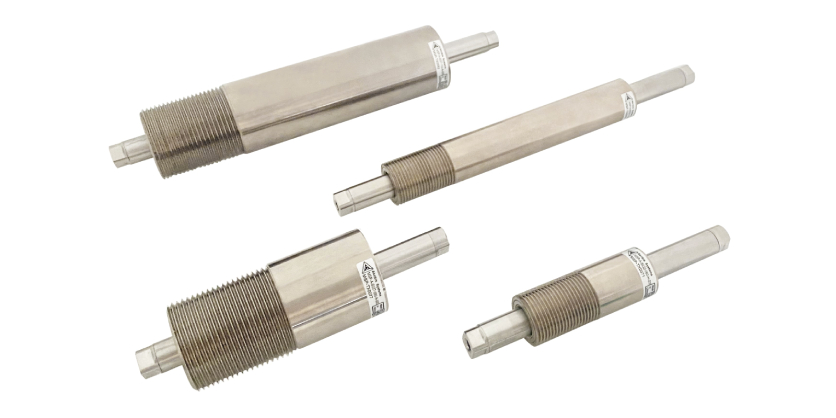

Akribis Systems is pleased to introduce its MSP-A Series magnetic springs. This spring family is an attractive choice for industrial z-axis direct drive module applications that call for a high-speed means of gravity compensation, self-locking capabilities to prevent unwanted component movement during power-off states or constant force within a specific travel range.

While air cylinders can also be used, they require an air system, an external power supply for control, and are usually expensive. Another option, mechanical springs, typically lack sufficient stiffness and consistent force.

MSP-A magnetic springs, however, deliver high-speed strokes and instant response without the need for external power and control, linear guides or expensive air systems. Leveraging the stored energy of permanent magnets inside a slider and stator, MSP-A magnetic springs maintain a constant direction and magnitude within a specific travel range without the high energy cost, damage to moving parts or greater space requirement often associated with traditional methods of gravity compensation. Applications include 3D printing, robotic, textile equipment, pumps and compressors.

About Akribis ASystems

Akribis Systems is a global designer and manufacturer of direct drive motors, stages, positioning systems and precision components for a wide range of industries. Akribis continually innovates and develops cutting-edge products that keep manufacturing, testing and inspection systems productive and reliable.

More Information

Related Product

Akribis: Frameless Direct Drive Rotary Motors Offer Many Benefits

When it’s time to specify a rotary motor for a space-constrained assembly, size and weight will factor into your decision. After all, you’ll want to get the best motor performance possible for the available space, and you’ll also want trouble-free integration into the system. Larger, heavier motors tend to be inefficient and can limit design flexibility. And, choosing the wrong motor can be costly. This article will describe a style of motor that is both compact and highly efficient, making it desirable for a wide range of precision machines and other space-limited applications.