The Emergence of Mechatronic Subsystems and Their Importance in Product Deployment

September 3, 2025

By Warren Osak, with Krystie Johnston

As automation systems become more complex and project timelines compress, the role of mechatronic subsystems has shifted from convenience to a necessity for many OEMs. From modular robotic actuators to fully integrated motion systems, subsystem-level design is enabling manufacturers to accelerate development cycles, reduce risk, and concentrate internal resources on differentiation rather than reinvention.

In this Q&A, Warren Osak, President and Founder of Electromate, discusses the emergence of mechatronic subsystems, their impact on deployment timelines, and why more OEMs are adopting integrated solutions over traditional component sourcing.

Q1: What defines a mechatronic subsystem, and how do they differ from traditional component-level designs?

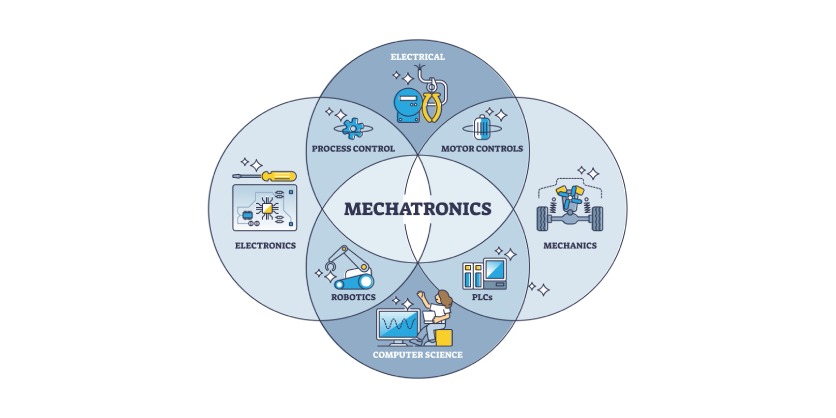

A mechatronic subsystem is a pre-engineered assembly that combines mechanical, electrical, electromechanical, and/or software elements into a cohesive functional unit. These subsystems typically include a motor, gearbox, encoder, drive, and often a controller—all optimized to work together.

Unlike traditional component-level sourcing, where each element must be individually selected, integrated, and tested by the customer, a subsystem is designed to handle a complete function—such as motion, positioning, or gripping—with minimal engineering effort on the user’s part. This reduces complexity, shortens design cycles, and improves reliability by leveraging proven interoperability.

Q2: What trends are driving the increased demand for integrated mechatronic subsystems across industries?

Several forces are converging. First, there’s relentless pressure to reduce time to market. Subsystems allow OEMs to skip months of development and integration by leveraging pre-validated platforms.

Second, as engineering teams become leaner, internal bandwidth is often better spent on high-level product innovation rather than low-level integration work. Subsystems shift responsibility for that integration upstream to vendors who specialize in it.

Third, demand for compact, high-performance machines in space-constrained environments is growing. Subsystems are optimized for form factor, thermal efficiency, and power density in ways that custom builds often aren’t.

Lastly, global supply chain volatility has made it riskier to rely on a scattered bill of materials. Integrated subsystems consolidate sourcing and support through a single channel.

Q3: How do subsystems improve speed to market and reduce engineering overhead for OEMs and machine builders?

Subsystems reduce development time by arriving pre-integrated, pre-tuned, and often with software libraries or control profiles already in place. That eliminates the need to write low-level firmware, tune PID loops from scratch, or troubleshoot misaligned feedback loops between mismatched drives and motors.

From an engineering perspective, you’re not redoing what’s already been done hundreds of times by the subsystem supplier. You’re building on top of a stable, validated base—allowing internal teams to focus on user interface, product performance, and compliance rather than core functionality.

Q4: What are some challenges companies face when adopting subsystem solutions, and how can they be addressed?

One concern is flexibility. Companies that prefer full control over each component selected may worry about being locked into a black box solution. That’s why modularity and documentation are critical—vendors must provide subsystems that can still be tuned, adapted, or reconfigured as needed.

Another challenge is vendor trust. Because the success of a subsystem hinges on proper integration, you need suppliers with deep engineering and integration experience plus technical support. Subsystems aren’t commodities—they’re engineered solutions that require partnership, not just procurement.

At Electromate, we address both by working with subsystem vendors who offer long-term support, transparent configuration data, and engineering documentation. We also provide sizing and selection services to ensure the required subsystem matches the specific performance requirements of the application.

Q5: Where do you see the evolution of mechatronic subsystems heading in the next 3–5 years?

Subsystems will continue to shift from general-purpose building blocks to highly targeted, application-specific solutions. We’re seeing more vendors offer pre-integrated assemblies tailored for defined tasks—such as Robotic Joints for exoskeletons and robots, AGV Wheeldrives, or Medication Delivery Systems—where the mechanical, electrical, electromechanical, and software elements are all optimized for a single use case.

In parallel, diagnostics and embedded firmware are becoming standard features, enabling faster commissioning and real-time status reporting. Subsystems are no longer just mechanical assemblies—they’re becoming data-generating assets that support condition monitoring, maintenance planning, and system-level coordination.

This evolution means customers will spend less time integrating and more time deploying. The question is shifting from “what components do I need?” to “what subsystem gets me operational quickly with the fewest unknowns?”

Q6: How does Electromate support its customers in selecting and deploying subsystem-level solutions?

We act as a technical partner, not just a value-added distributor. Our engineering team assists customers in designing mechatronic subsystems, evaluating subsystem architectures, and selecting matched components from leading vendors.

We specialize in high-precision, high-reliability environments, and we’ve compiled a portfolio of mechatronic subsystems that meet demanding criteria for accuracy, repeatability, and form factor. Whether it’s a robotic joint, an integrated programmable linear actuator, or a bespoke embedded mechatronic subsystem, our focus is always on mitigating design risk, accelerating product development cycles, and streamlining manufacturing.

Author Bio:

Warren Osak is the Founder and President of Electromate, a Canadian value-added distributor specializing in Robotic and Mechatronic Solutions. With over 35 years of experience in motion control, mechatronic, and robotic integration, Electromate has become a key partner to companies seeking subsystem-level solutions that reduce complexity and improve product time-to-market.

More Information

Related Stories

Related Stories – A Guide to Mechatronics

Part 1: Introduction & Fundamentals

Part 2: Composition of a Mechatronic Subsystem

Part 3: Strategies for Integrating Mechatronic Subsystems

Part 4: Software & Programming

Part 5: Tools & Languages in Mechatronics Software Development

Part 6: Applications of Mechatronic Subsystems