Four Tips for Designing Tamper-Evident Late-Stage Customization Solutions

June 29, 2021

Serialization legislation is requiring pharmaceutical manufacturers to ensure that labels printed at a late stage contain all data necessary for compliance. Since many product labels are customized by markets, customer, or product type, adding variable data to labels or packaging is a way to avoid stocking individual packaging materials for each variant.

The flexible production of smaller batch sizes has also introduced new requirements for automatic and fast changeovers. If you’re a pharma manufacturer, how can you implement a flexible, tamper-evident solution for late-stage customization in low- and medium-volume production?

Fortunately, late-stage customization can be an opportunity for finding a solution that handles both serialization and the production of small batch sizes without any loss of operational effectiveness. Let’s take a look at the best way to do this.

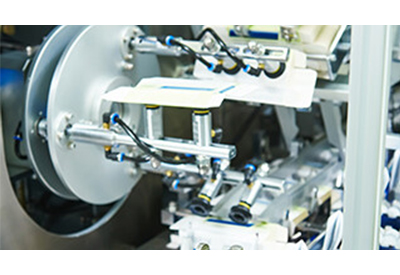

1. Combine manual feeding with robotics and other automated tasks.

When building a flexible serialization station, it’s a good idea to find a way to seamlessly combine manual feeding, robotics, printing and sealing. Once products are fed manually, the robotic technologies can automatically separate and transfer them to the print head for customization via variable data, such as product codes, serial number and lot number.

2. Load master data from the serialization database or ERP system.

You can prepare orders and load the master data from the serialization database or ERP system. Set-up can be carried out via a menu, including the loading of variable data print profile and the position of the tamper-evident seal, which is applied to the carton by a robot.

3. Employ robot-guided machine vision for label inspection.

The station can include a robot-guided machine vision system to checks label presence and print quality and also validate text and the DataMatrix code. The system will reject products with poor print quality, incorrect printing, or insufficient seals.

4. Take advantage of state-of-the-art touchscreen technology.

The serialization station can include product weighing and can be operated via a large, intuitive industrial touchscreen. It can generate all the reports, including a production report, error reports, the status of the serial numbers used, and an Audit Trail Report. A full audit trail, which is part of the regulatory requirements, assures record integrity and security.