Universal Robots to Power Next-Gen Laser Welding, Finishing and Plasma Cutting at FABTECH 2025

September 3, 2025

Universal Robots (UR), a leader in collaborative robotics, is set to elevate fabrication automation at FABTECH 2025 in Chicago, IL, Sept. 8-11, with a range of new pioneering cobot solutions.

“Cobot welding continues to evolve at a rapid speed,” said Jean-Pierre Hathout, President of Universal Robots. “Eight years ago, we introduced North America’s first cobot welder at FABTECH 2017, performing straight MIG-welds. Today, new robot control features combined with the innovation of our partner ecosystem continue to push the envelope, handling applications that few believed possible just a handful of years back. This event is the perfect platform to experience how UR robots are transforming the entire fabrication workflow.”

FABTECH attendees first to discover new UR robot

The UR President previewed a brand-new robot, engineered specifically to meet the toughest challenges in welding with outstanding reach, stability, and precision.

“Designed to excel under pressure – whether on long seams, complex parts, or repetitive passes – this new model will showcase how UR robots are not just keeping pace with industry demands but setting the benchmark for what’s possible,” said Hathout, adding that the new robot will make its global debut in both Universal Robot’s own FABTECH booth #B13045, and in the booths of partners Hirebotics, THG Automation, and Vectis Automation.

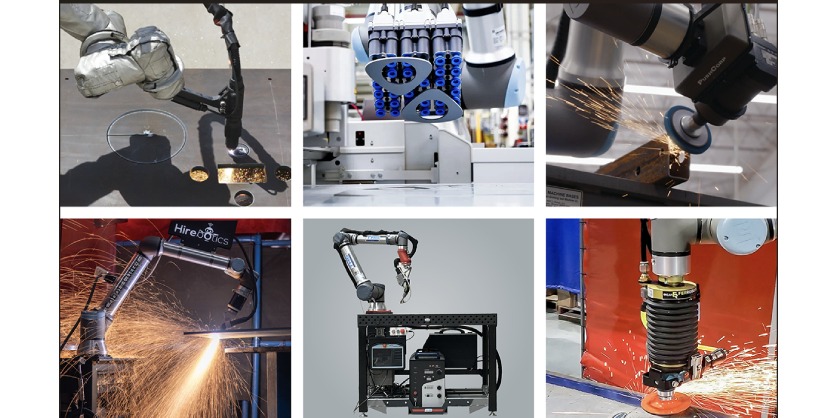

The UR President also highlighted new plasma cutting and laser welding applications coming to FABTECH, showcasing the most recent rugged and complex fabrication tasks that Universal Robots now handle.

Automated plasma cutting delivers weld-ready parts

Automated plasma cutting is one of the fastest-growing applications for cobots, thanks to its substantial impact on welding efficiency. Traditional hand-cutting often results in inconsistencies, making welding more challenging, whereas robotic cutting delivers parts that are ready for seamless robotic welding.

This synergy is showcased in booth #B13051 by Hirebotics, whose Cobot Cutter provides fast, precise cuts on steel, stainless, and aluminum, eliminating manual rework. Hirebotics will also introduce multipass welding, through-the-arc seam tracking, and AI-powered weld setting recommendations.

Vectis Automation is advancing this field further in booth #B13031 with the Vectis Shape Tool, which allows complex shapes to be cut—aligned or projected onto curved surfaces—opening up new possibilities in fabrication. Their Clarity™ Data Insight Dashboard captures valuable production metrics for optimized program efficiency, while enhanced software delivers advanced weave patterns and AI-driven path optimization, helping users master even intricate wrap and transition jobs.

Both plasma cutting solutions are also highlighted in plasma cutting market leader Hypertherm’s booth #A4513.

Cobot laser welding goes mainstream

Laser welding with cobots is now entering mainstream adoption, overcoming initial concerns about safety, complexity, and costs through advances in control software, turnkey safety engineering, and fiber laser affordability. At booth #B13053, THG Automation’s URW-2LF Collaborative Laser Welding System leverages a UR robot and an IPG fiber laser to offer cleaner, faster welds with minimal heat distortion—plus laser-based pre-cleaning and discoloration removal for superior aesthetics and workflow simplification.

Versatile grinding,finishing, and handling

At Universal Robot’s booth, finishing and grinding solutions also take center stage, as PushCorp pairs a UR30 robot with the STC2002 servo spindle and AFD120 active force device, enabling automated, uniform surface finishing that adapts to part irregularities. Ferrobotics will demonstrate its cobot active force control (ACK-F), designed for robots with payloads of 8 kg and above. The demonstration cell operates flexibly with UR robots, enabling users to easily attach and program up to 15 different finishing tools on site. By combining Ferrobotics’ real force control technology with the intuitive operation of Universal Robots, the solution provides the ideal entry point for first-time users while also supporting customers who want to scale their finishing operations.

Material handling is equally essential in fabrication, from machine tending to automated picking, stacking, and palletizing. The company’s fastest robot, the UR15, will be equipped with Schmalz’s new FMG matrix area gripper, an automated solution suitable for flat, suctionable workpieces and equipped with an air-saving function that can reduce compressed air use by up to 80%, ideal for sheet metal production.

Attendees will have opportunities for hands-on demos, networking, and expert insight into the future of fabrication. In addition, Will Healy III, Teradyne Robotics’ global industry leader for metal fabrication, will offer a series of impactful presentations as part of FABTECH’s conference schedule:

Monday, September 8

- Introduction to Automation Technology – A Practical Guide to Learning & Implementing Automation on the Shop Floor (8:30–9:30am)

Wednesday, September 10

- Challenging Industrial Welding Automation & Fabrication Paradigms with Cobots (8:30–9:30am)

- How Artificial Intelligence & Automation Are Impacting Metal Fabrication from the Office to the Shop Floor and Everywhere In-Between (10:00–11:00am)

- The Impact of Automation & AI in Metal Stamping: Real Transformations of Business Management, Manufacturing Processes & Machines (3:00–4:00pm)

More Information

Related Story

Universal Robots Launches UR Studio – A New Online Simulation Tool Making it Simpler than Ever to Customize the Optimal Robot Cell

Universal Robots (UR), one of the world’s leading collaborative robot (cobot) companies and a part of Teradyne Robotics, presented UR Studio, a powerful online simulation tool built on PolyScope X, UR’s most advanced, open and AI-ready software platform on June 24.