Comau Selected To Support Foton Daimler’s Localized High-End “Actros” Truck Production

December 22, 2022

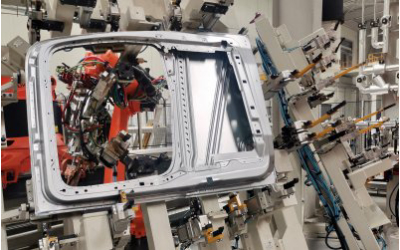

-Comau has built a state-of-the-art welding solution to produce the customer’s first heavy-duty truck in China

– Featuring 100% process automation, the system combines advanced Comau technology with powerful vision systems and the flexibility to handle complex model management

-The automatic welding set-up fully supports the targeted annual production capacity of 50,000 units

Comau has built an advanced, automated welding solution for Beijing Foton Daimler Automotive Co., Ltd (BFDA), a joint venture between Daimler Trucks AG and the Chinese truck manufacturer Foton Motor. In doing so, Comau is helping support BFDA’s first localized heavy-duty truck for the Chinese market, the “Actros”, which is based on the Mercedes-Benz global platform and uses Daimler’s most advanced truck technology.

Featuring 100% process automation, the Comau-designed production line is engineered to be completely flexible in order to handle complex model management and variable output management. With a target annual production capacity of 50,000 units, Comau’s welding solution will meet both the customer’s current and future production requirements.

Under the scope of the project, Comau’s engineering team was tasked with mastering the Daimler Integra 6 standard to create an automated, flexible, intelligent and digital welding line for both the door area and the framework of the instrument panel.

Built to ensure cycle efficiency and streamline workflows, the solution features proprietary Comau products, such as RH-Clean, an automatic cleaning roller device that can be used with different types of rollers and pre-hemming tools, and a quality-control vision system that uses QUISS camera detection and is equipped with a kick-in/kick-off process to ensure the quality of the parts after gluing. Finally, the project also leverages virtual commissioning technology to help test and optimize the new production line while shortening the actual commissioning time, reducing labor hours and reducing potential post-site commissioning risks.

“Throughout this successful collaboration, the Comau team has played an important role in improving the competitiveness of our products. We are particularly impressed with their expertise in various aspects such as design, reliability and cost.” mentioned William Sparenberg, Head of Mercedes Benz Truck Factory.

“We are honored to have been selected by Foton Daimler to work on this milestone which paves the way to localizing its first heavy-duty truck. Daimler is a global leader in the automotive industry, not only because of its large volume of business, but also because of its pursuit of technological advancement,” said Gaetano Cantalupo, Comau Head of Countries Cluster APAC. “Winning this project is a recognition of Comau’s capabilities, expansion of its customer base and expansion into new business modules.”

Mass production of the high-end Actros truck is expected to start in Q2 2023.

To learn more, click here