TwinCAT CoAgent and TwinCAT Machine Learning Creator for AI-assisted automation

November 25, 2025

Unlock optimization potential even more easily with advanced AI functions

Artificial intelligence has long since found its way out of laboratories and research facilities and into everyday life – and is also proving to be a key driver of innovation in industrial automation. Beckhoff recognized this trend early on and integrated AI directly into the control environment. With TwinCAT Machine Learning, AI models can be executed in real time directly on the machine controller and thus literally woven into the PLC code. Furthermore, TwinCAT CoAgent and TwinCAT Machine Learning Creator allow process and automation experts to use AI technologies directly for their applications. Recent functional enhancements to these products show how consistently Beckhoff is driving forward the democratization of AI in automation.

Two approaches to the use of artificial intelligence have emerged in industrial practice: task-specific AI and agentic AI. Task-specific AI handles clearly defined tasks such as visual quality control, predicting machine failures, or locating objects. It is based on domain-specific data and is closely integrated into the control environment – for example with TwinCAT Machine Learning Creator and TwinCAT Machine Learning. On the other hand, there is agentic AI, i.e., AI-based assistance systems built on generative models.

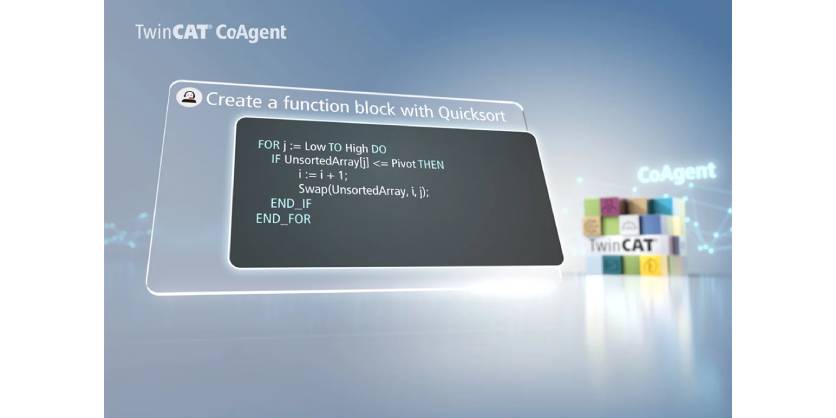

These systems support engineers and machine operators through dialog-based interaction, automated code generation, or error analysis during operation – implemented with TwinCAT CoAgent. Both approaches complement each other by addressing different levels: task-specific AI increases efficiency and quality directly in the machine process, whereas agentic AI makes everyday engineering and servicing easier – from development to commissioning and ongoing optimization.

More efficiency in development, service, and machine operation

TwinCAT CoAgent for Engineering supports control programmers in a variety of tasks – from precise code suggestions and smart optimizations through to automatic documentation. Through integration into existing projects, verified content can be adopted directly. In addition, the CoAgent enables quick access to the Beckhoff documentation system, the development of user-friendly HMI controls, and the simple configuration of complete I/O topologies via chat or natural language.

For developers, this means less time spent on routine work and search tasks, a significant acceleration in day-to-day project work, and more freedom to focus on demanding automation tasks. Thus, TwinCAT CoAgent is establishing itself as a personal assistant that makes the entire engineering workflow more efficient in the long term.

With TwinCAT CoAgent for Operations, Beckhoff brings agentic technology directly into machine operation. The CoAgent continuously monitors process values, log files, and KPIs, detects deviations, and initiates a structured problem-solving process together with service personnel:

1. Form a hypothesis.

2. Perform evidence-based diagnosis.

3. Provide concrete suggestions for action, including step-by-step instructions.

Agent-supported error diagnostics make it possible to evaluate alarm messages in context – e.g., by correlating increased power consumption, falling throughput, and log warnings. This allows false alarms to be reduced and critical faults to be prioritized. Typical potential benefits include a significantly shorter time to resolution (TTR), a higher first-fix rate for the most common error patterns, and a noticeable workload reduction for service personnel. Another advantage lies in the documentation: TwinCAT CoAgent creates detailed, target group-oriented service reports for any period of time as desired.

These reports include root cause analyses, impact, duration, recommended corrective actions, and follow-up of outstanding issues. Shift reports can also be generated automatically – including KPIs, trend charts, and unresolved maintenance tasks scheduled for the next shift. Thus, TwinCAT CoAgent for Operations is being established as an interactive service agent that makes ongoing operations more intelligent, from faster troubleshooting and improved transparency to a consistently higher quality standard in reporting.

In summary, Beckhoff TwinCAT CoAgent proves to be a powerful AI assistant over the entire automation lifecycle – from code generation in engineering to error diagnostics during operation. The open architecture of TwinCAT CoAgent enables the integration of different language models and flexible combination with customer-specific extensions – supported by interface standards such as the Model Context Protocol (MCP).

For example, a company can provide its own knowledge database as an MCP server and integrate it seamlessly with the CoAgent. By extending the product to cover the entire lifecycle, all development and service processes can be accelerated, complexities reduced, and downtimes significantly shortened. Developers benefit from more efficiency and freedom in their day-to-day project work, while service teams can respond more quickly and receive targeted support. The increased flexibility and openness of the system also ensures investment security and future viability.

Automatic AI model creation for signal and time series analyses

The TwinCAT Machine Learning Creator (MLC) from Beckhoff is aimed at automation and process experts and adds automated AI model creation to the TwinCAT 3 workflow. This opens up the potential of artificial intelligence for smaller companies too – with benefits in terms of competitiveness and in dealing with the increasing shortage of skilled workers. At the same time, the tool also makes work easier for AI developers: as a “version zero generator”, it automatically creates initial model variants, reduces sources of error, and accelerates the development process.

In addition, extensive methods are available to represent the behavior of the models transparently, compare variants, and support auditing processes through automated report generation. With the provision of the right tools, those directly affected – the automation engineers – can solve their challenges themselves. This way, the expertise becomes more deeply embedded in the company and is built up over the long term.

The model that has been automatically trained with TwinCAT MLC can be exported in the ONNX open standard format and is optimally adapted to the real-time requirements in the control environment in terms of latency and accuracy. The focus to date has been on AI-supported image processing. With TwinCAT MLC Signals and Time Series, Beckhoff is expanding the functional scope of the Machine Learning Creator: In addition to image processing (TwinCAT MLC Computer Vision), signals and time series can now also be analyzed efficiently. Typical applications include:

- classification (e.g., for quality inspection)

- forecasting (e.g., to predict energy consumption or wind speed)

- anomaly detection (e.g., in condition monitoring)

Signals and time series include both the progression of a single signal over time or over other variables (such as frequency, wavelength, distance, or angle) as well as the development of several signals in parallel over different dimensions, e.g., the progression of pressure, temperature, and electrical power over time.

Signal and time series analysis opens up a wide range of possibilities in industrial applications, especially as comprehensive machine data is already available with PC-based control from Beckhoff. Numerous TwinCAT tools can be used for convenient data collection directly from the control process, such as TwinCAT Scope View, Analytics Logger, Database Server, or Data Agent.

Anomaly detection and condition monitoring

A central area of application for signal and time series analysis is anomaly detection: the temporal correlation of disruptive events – such as faulty signal transmissions, power supply fluctuations, operating errors, or environmental conditions – allows causes to be reliably identified. Typical applications include:

- detection of motor malfunctions (bearing damage, imbalance, mechanical problems) based on current, vibration, or acoustic signals

- diagnosis of pump and compressor faults via current and temperature data

- detection of leaks in hydraulic or pneumatic systems via pressure monitoring

- wear detection on milling and drilling tools based on spindle currents

Quality assurance and process monitoring

There is also new potential in the field of quality assurance. Sensor-based, non-optical end-of-line tests can evaluate electrical properties (e.g., impedance curves) or geometric variables. Inline analyses enable process-integrated quality monitoring for applications such as:

- welding processes via current and voltage curves

- cutting and packaging processes based on servo motor currents

- sealing, grinding, or forming processes based on motor currents

- kneading and fermentation processes in food production using temperature-time profiles

- complex processes such as crystal growth in semiconductor production

Process optimization and energy efficiency

In addition, time series analysis contributes to process optimization and energy efficiency. Examples include the dynamic adjustment of adaptive process parameters (e.g., feed rate, pressing force), the optimization of energy consumption based on load profiles and forecasts, or the predictive control of complex systems. In the context of wind power, for example, the nacelle and rotor blades can be optimally aligned based on the predicted wind direction and speed.

More Information

Related Story

Beckhoff Nominated for Best of Industry Award 2024

Beckhoff is delighted to announce that they has been nominated for the Best of Industry Award 2024 in the Artificial Intelligence category. This prestigious award, presented by the Vogel Communications Group, honors outstanding innovations in the industry.

Their TwinCAT 3 Machine Learning Creator is one of the top 3 innovations in its category. Votes were open for 5 months, and over 20,000 votes were collected across 15 different categories. Beckhoff is proud to be among the finalists and would like to thank everyone who supported them by voting.