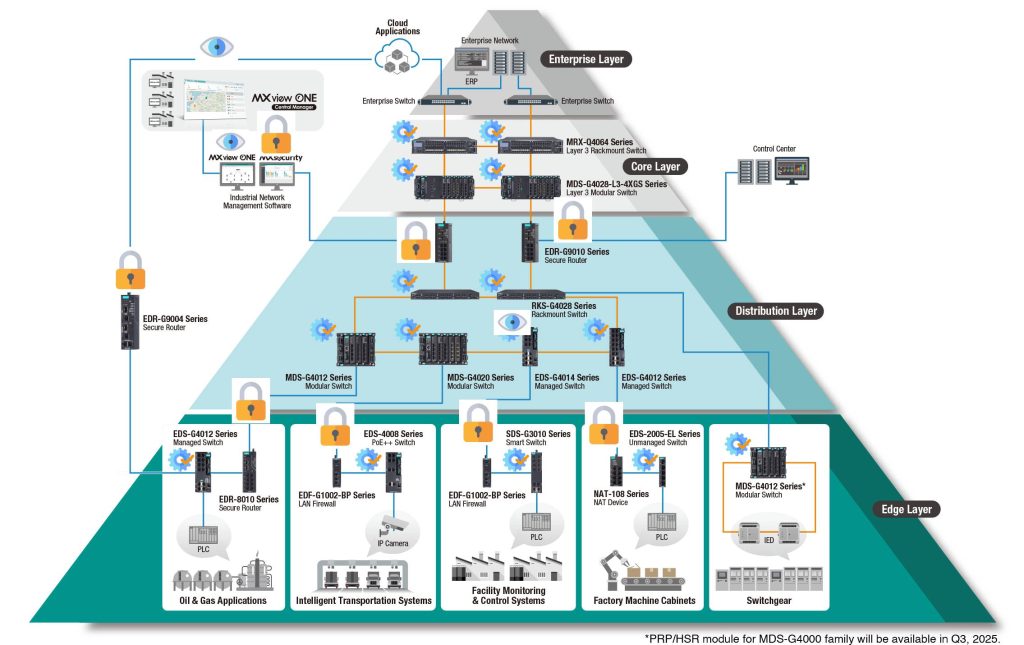

Futureproof Industrial OT with Moxa’s Secure Edge-to-Core Networking

October 1, 2025

IT/OT convergence is essential for any business aiming to innovate. More than ever, industrial networks must advance to enable seamless integration between OT and IT systems. When a critical network connection fails, it can result in thousands of dollars lost per minute due to downtime or even jeopardize public safety. This is why fully leveraging OT networking has become a necessity rather than an option.

Moxa is dedicated to helping industrial networks transition to the next generation of networking. With Moxa, businesses can develop reliable and adaptable networks designed for the future, ensuring seamless data connectivity and integration, and enabling smooth preparation for the shift toward a digital future.

You May Be Curious … Why has interoperability become a fundamental requirement?

As OT environments continue to advance through digitalization and become increasingly connected with the broader IT ecosystem, seamless collaboration between various systems and network devices has transitioned from a desirable feature to a fundamental requirement. This change offers several key benefits:

- Streamlined operations: Network solutions with high interoperability integrate more smoothly, reduce downtime caused by communication errors, and improve the efficiency of operational workflows.

- Easier expansion: Compatibility with a wide range of systems and protocols makes it simpler to add new devices and expand the OT network without major integration difficulties.

- Simplified management: Solutions supporting multiple protocols allow centralized management through existing SCADA or PLC/HMI platforms, saving valuable time and resources.

You May Be Curious … Why is cyber-resilience increasingly critical?

As cyberattacks become more sophisticated—utilizing technologies such as AI and machine learning—traditional prevention-focused security approaches are no longer sufficient. Consequently, organizations are increasingly prioritizing cyber-resilience: the ability to withstand, recover from, and adapt to cyber threats to minimize their impact and ensure operational continuity. This represents a practical shift in cybersecurity strategy.

In industrial environments, this challenge is further complicated by the need to deploy network security solutions that are straightforward for OT operators to manage, while avoiding any operational disruptions. Efforts to enhance cyber-resilience typically focus on three key areas:

- Minimizing the attack surface: This includes segmenting the network into zones, securely configuring devices, and employing robust vulnerability management tools to reduce exploitable weaknesses.

- Enhancing security incident detection: Continuous monitoring of network traffic, analyzing logs to detect early anomalies, and implementing IDS/IPS systems help identify unauthorized access and unusual activities promptly.

- Accelerating incident recovery: Establishing incident response plans and performing frequent secure backups facilitates quicker recovery and helps restore operations rapidly after an attack.

You May Be Curious … What is a unified network, and how does it relate to time-sensitive networking (TSN)?

Unified industrial networks and time-sensitive networking (TSN) are deeply connected. In particular, TSN provides the technological basis required to unify network infrastructures . Here’s a concise overview of these two concepts:

- Unified networks: These networks combine various systems and types of network traffic—such as control data, video, and standard IT data—into a single, standardized Ethernet infrastructure. This strategy eliminates traditional silos created by proprietary industrial protocols and isolated IT/OT systems.

- TSN: A set of IEEE 802.1 standards that extend standard Ethernet by enabling deterministic and time-synchronized communications. TSN allows multiple traffic types with different quality-of-service (QoS) requirements to coexist on one Ethernet network.

For industrial settings that demand real-time control and synchronization, TSN’s deterministic and synchronized communication features provide the foundation for constructing future-proof unified networks. Merging IT and OT on a single, robust network guarantees timely and dependable data delivery for sensitive applications such as robotics and motion control.

With Futureproof Network Infrastructure, You Can …

Facilitate Seamless Communication

Moxa provides dependable edge-to-core networking solutions that fulfill the demands of various network layers, support both current and future data connectivity requirements, and ensure uninterrupted operations.

Moxa’s secure networking solutions simplify the protection of OT networks against cyberthreats while mazimixing system availability.

Optimize Operational Efficiency

Moxa offers centralized network management solutions that simplify network oversight, enabling you to plan, deploy, operate, and maintain your network with greater ease.

Key Tips for Building Futureproof Industrial Networks

Concerned about the challenges of IT/OT convergence? Here’s some valuable advice to help you build a network infrastructure prepared for the demands of tomorrow. Download now

Explore Moxa’s Solutions

Moxa’s future-proof industrial network solutions are crafted to assist businesses in building infrastructure that meets both current and future application demands, while fully leveraging the integration of IT and OT systems.

More Information

*For any further information, please contact us via sales@manuauto.com.

Related Story

MOXA Next-Generation LAN Firewalls: Enhancing Industrial Security and Reliability

Cyberattacks on critical infrastructure have become an all-too-familiar reality. While no longer shocking headline news, their effects are far-reaching, disrupting essential services that people and organizations rely on daily. From power grids to transportation systems and water treatment facilities, these infrastructures are at the heart of modern life and are highly vulnerable to cyber threats.