Redefining Non-Invasive Temperature Measurement

May 14, 2025

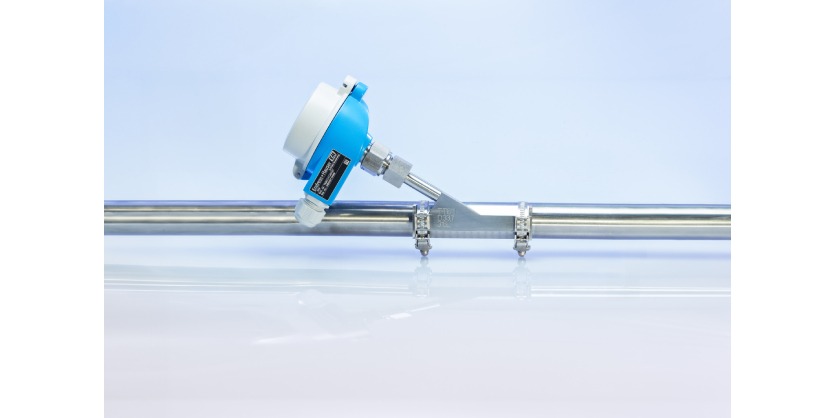

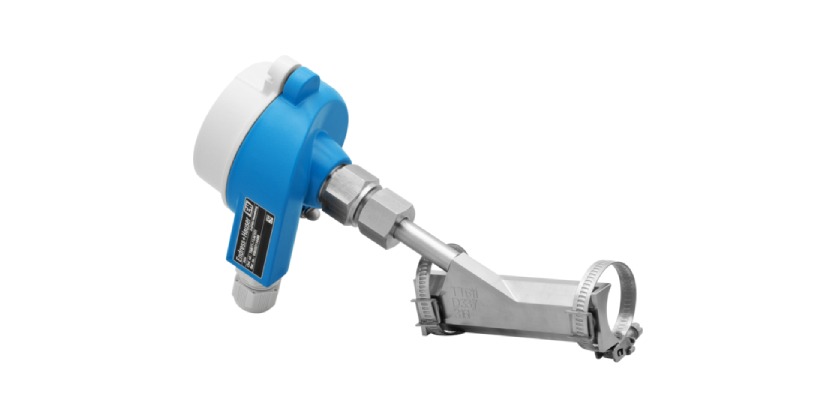

iTHERM SurfaceLine TM611 provides accuracy and response time comparable to invasive temperature measurement.

The non-invasive thermometer iTHERM SurfaceLine TM611 by Endress+Hauser can be used across all industries for a wide range of demanding industrial applications. The surface-mounted thermometer measures process temperature without the risk of leakage and flow disruption. A specially designed thermal coupling element provides ideal thermal conductivity to the sensor and reduces ambient influences, resulting in excellent measurement performance.

Increased safety for personnel, plant,and the environment

Non-invasive thermometers measure the process temperature on the surface of a pipe without penetrating the pipe wall. This eliminates the risk of leakage, process contamination and flow disturbance. In addition, there is no wear on thermowells or influence from vortex-induced vibration, reducing the risk of failure and plant downtime.

Redefining non-invasive temperature measurement

The Endress+Hauser surface thermometer iTHERM SurfaceLine TM611 features a thermal coupling element with advanced geometry specifically designed for the pipe diameter, providing a large contact surface that optimizes heat transfer to the sensor. This advantage is further enhanced by an RTD/TC sensor with low thermal mass that fits precisely into the coupling element, eliminating any air gaps. A special heat transfer material applied to the coupling element compensates for any pipe imperfections. This ingenious product design results in accurate measurements without the need for error-prone electronic compensation, calculations or algorithms.

Significant cost and time savings

In contrast to traditional invasive methods, non-invasive thermometers offer significant time and cost savings at various steps from project engineering to procurement, installation and operation.

Development and design times are drastically reduced by eliminating the need for wake frequency and insertion depth calculations. Installation becomes more economical with reduced material expenses for thermowells, nozzles, pipe extensions and flanges. This cost efficiency even extends to services such as weld seam tests and material certification. In addition, non-invasive thermometers minimize lifecycle costs by eliminating risks such as thermowell breakage, leakage and regular inspection.

Designed to meet all requirements

The product is equipped with all relevant international certifications, including explosion protection according to ATEX, IECEx, CSA and NEPSI and functional safety (SIL). In addition, iTHERM SurfaceLine TM611 is available with the full range of Endress+Hauser iTEMP temperature transmitters, including all common analog and digital communication protocols, optional Bluetooth® connectivity and advanced diagnostics according to NAMUR NE107. The stainless steel clamps ensure easy and safe installation, making it ideal for retrofitting or temporary measurements.

These features establish the non-invasive thermometer as the perfect solution for energy and safety monitoring, as well as for demanding applications, such as high flow velocities or process pressures, highly viscous or corrosive media and applications including pigging or small pipe diameters.

Interested in learning more? Contact Endress+Hauser.

More Information:

Non invasive temperature measurement

Related Story

Endress+Hauser to Supply Canadian Process Sector from Europe to Minimize Tariff Effects

Endress+Hauser announced it will supply the Canadian process sector with its industrial analysis and measurement instruments and other products directly from its production facilities in Europe to minimize tariff effects.