Xaba’s xCognition is Incredible

February 27, 2025

Deploy and program your automated factory in 75% less time, while achieving the the performance of multi-million dollar CNC machines with low cost commercial robotics systems with Xaba’s xCognition.

Today’s robotic systems lack intelligence and precision, leading to inaccuracy, inconsistency, poor quality and a significant amount of human supervision leading to high adoption and deployment costs.

Their use is made even more challenging due to a lack of intelligence and precision leading to inaccuracy, inconsistency, poor quality.

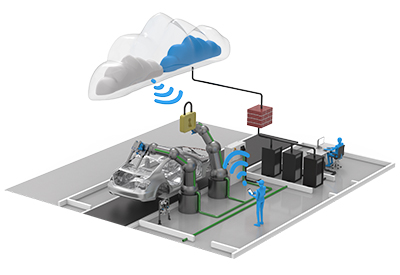

xCognition automates the generation of robotic programs, and works with Xaba’s proprietary control system that dramatically increases the precision, consistency and flexibility of any commercial industrial robotics system.

Automated program generation

xCognition uses an AI-powered interface to capture your operator’s intent with little to no training required, or can be driven by sensor input such as a vision system. It then automatically generates machine programs in the required language for your robotics workcell.

AI-powered calibration for accuracy and precision

xCognition also uses AI to learn precisely how and where a robot needs to move, automatically generating its control programs and self-correcting the robot when it gets off course, dramatically increasing precision and consistency.

Outcomes

- 10x improvement in accuracy and repeatability using commercial industrial robotics arms.

- 70% reduction of time required to program your robots.

- 75% reduction of cost reduction to adopt and deploy automation.

- 60% increase in throughput.

Easy to deploy

- Works with both old and new robotic systems.

- Integrates with all robotics OEMs via proprietary universal ROS interface.

- Requires little to no operator training.

How it works

Automated Programming Module

Uses multiple AI-based modules to capture and interpret operator input and/or sensor input, and then automatically translates that intent into the execution-ready, OEM-specific robotics program while also accounting for the specific parameters of the process you are executing.

Robotics Control System

Xaba’s proprietary Deep Artificial Neural Network software directly controls the motion of each robot joint or machine axes, resulting in a significant increase in the accuracy, repeatability and consistency of any robotics work cell.

More Information

Case Study: xCognition Robotics Control System

Related Story

Xaba Inc. Gives Cognition to Machines, Disrupts Industries with Quantum Leap for Intelligent Automation

Massimiliano Moruzzi, CEO of Xaba Inc. is an Aerospace Engineer whose innovations have impacted products and solutions for leading companies in aerospace, automotive, and energy. Xaba Inc. recently won the 2024 ABB Startup Challenge that asked companies around the world to present their solutions that will make an impact on the energy transition by leveraging artificial intelligence. Moruzzi discusses the disruptive technology that won and why it is time to change the way industrial automation is approached.