RoboDK and Comau Partner to Offer Improved Robotic Simulation and Offline Programming

March 7, 2024

The latest version of Comau Roboshop Next Gen software now fully integrates with RoboDK, bringing unparalleled benefits to the world of automation

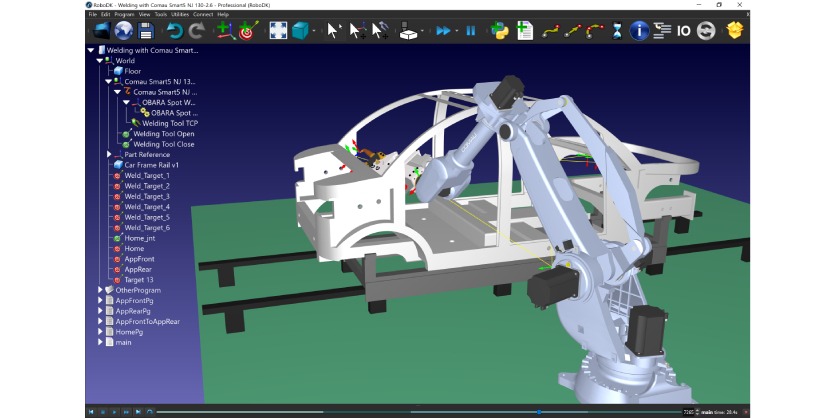

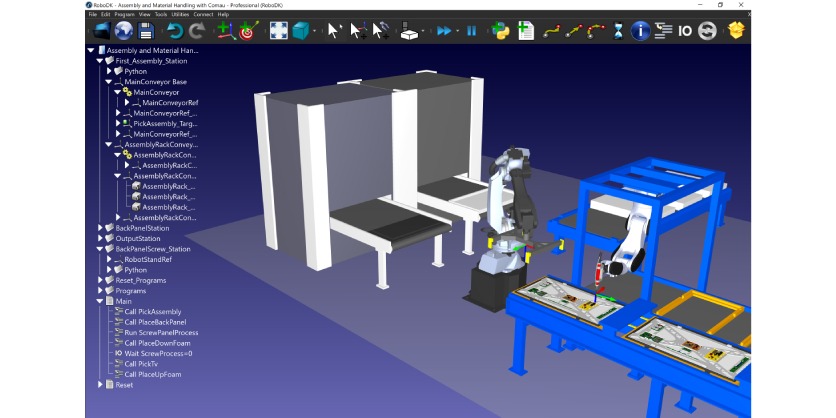

RoboDK, a pioneer in the world of robotics simulation and offline programming, announces its strategic partnership with Comau, a global leader in advanced automation solutions and robot manufacturer. The latest version of Comau Roboshop Next Gen software seamlessly integrates with RoboDK, making simulation more advanced.

This collaboration solidifies RoboDK’s presence in the OEM market, marking a significant step as an embedded solution. Comau users can now enjoy the benefits of RoboDK directly due to RoboDK’s integration into Comau’s Roboshop Next Gen software suite. This integration allows users to easily simulate and program robots using advanced CAD to path features, import 3D Models, detect collisions, integrate with external axes such as turntables and linear rails, support multiple robot cells in the same project, improved integration with CAD/CAM software and use advanced simulation features such as conveyors and grippers. This allows Comau robot programmers to easily use Comau robots for advanced manufacturing applications such as robot machining or 3D printing.

In addition to these technical benefits, the collaboration also introduces support for Realistic Robot Simulation (RRS), providing accurate path and cycle time estimates. This advancement aims to provide businesses with a clear understanding of robot behavior and precise cycle time details, ensuring more efficient and optimized robot operations.

Using RoboDK it will therefore be possible to create a program in a very intuitive way. Then through Roboshop Next Gen, it can be executed in a simulation with a Virtual Control and then deployed on a real robot!

While this partnership marks a significant step for embedded solutions, RoboDK remains committed to its ongoing collaboration efforts with various partners, reinforcing its dedication to make automation more affordable across industries.

Phillip from the RoboDK team shares his insights on the collaboration: “By working closely with Comau we were able to improve our integration with Comau robot controllers while keeping everything backwards compatible. The level of integration resulting from this partnership is immensely beneficial for all Comau users.”

Albert Nubiola, CEO and Founder of RoboDK, comments: “We’re excited to partner with Comau and bring RoboDK’s advanced simulation features to Roboshop software at an unbeatable price. By working together, we were able to make advanced simulation more affordable.”

He continues: “Our mission is to build a software platform where users can program any robot arm using the same software, democratizing robot simulation and programming. Partnering with Comau, one of the world’s premier robot manufacturers, marks a pivotal moment for us.”

RoboDK distinguishes itself by embracing modern technologies, thus setting itself apart from peers reliant on older and more expensive software frameworks. With modern tools, integrations, competitive pricing, and an array of complementary features—including advanced CAD to path features, integrations with CAD/CAM software, collision checking, singularity avoidance, robot calibration and brand-agnostic offline programming—RoboDK stands out as a frontrunner. Users have access to extensive documentation and libraries at no cost. Moreover, the company’s website, documentation and YouTube channel offers a rich collection of tutorials.

Alessandro Piscioneri, Head of Product and Solutions Management, remarks: “Comau has recently launched the latest version of RoboShop Next Gen, that allows our customers and partners to program our robots and simulate their functionalities in an easy and fast way. Thanks to the collaboration with RoboDK, a truly innovative company in robot programming and 3D simulation, it is possible for companies to create their virtual environments and simulate their applications in a matter of minutes, while using Comau’s software. It’s important to emphasize that this solution is aimed at both experienced and new programmers, in an effort to make robotics easier to design and use. This is a priority for us and we are investing heavily in this direction”.

More Information

Related Story

RoboDK TwinTool Offers Fully Automated Tool Calibration for Industrial Robots

Canadian robotics software provider RoboDK has released TwinTool, an application that offers fully automated robot tool calibration for industrial robots. TwinTool is a cost-effective, quick, and easy solution to improve the tool’s accuracy in a wide variety of manufacturing applications. It is a competitive alternative to costly and complex robot calibration services currently available on the market.