Festo Launches HPPF Diminutive Flat Parallel Gripper for Space-Constrained Applications

December 6, 2023

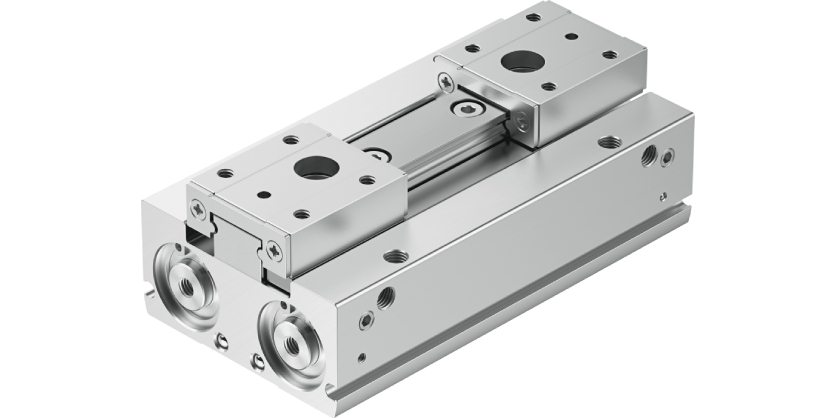

Festo’s HPPF diminutive flat parallel gripper not only delivers great force in tight spaces, it’s also extremely well-priced

Thanks to manufacturing innovations achieved on a new production line, Festo’s HPPF diminutive flat parallel gripper not only delivers great force in tight spaces, it’s also extremely well-priced. HPPF ranges from 19 mm to 41 mm among its four sizes: 8, 12, 16, and 20. The stroke ranges from a narrow 8 mm to a wide 80 mm, with gripping forces from 60 N to 377 N. These specs make the new HPPF ideal for space-constrained applications in small parts and electronics assembly. That includes battery manufacturing, since each HPPF contains less than 1% copper/zinc/nickel.

Twin piston rack and pinion motion and ball bearing guides give these units high accuracy – ≤ 0.03 mm to ≤ 0.06 mm – and maintenance-free long-service life. Twin pistons provide these compact units with a high grip force. Units are symmetrical for flexibility in mounting. Both sides feature a C-slot for sensors. Machine builders can adjust the stroke and there is an elastic cushioning option. Weight is exceptionally low – ideal for today’s smaller footprint, more sustainable machines – 68 g for the smallest unit and up to 1,326 g for the largest.

Festo at a glance

Festo, the world’s leading supplier of automation technology and technical education, is deploying its products and services to meet the challenges of digitization and smart production. Founded in 1925, the family-owned company based in Esslingen, Germany supports a wide range of needs for advanced solutions in factory and process automation.

In Canada, Festo has been supporting Canadian industry for almost 50 years, continuously elevating the state of manufacturing in this country with innovative products, optimized motion control solutions and unrivalled support. Globally, some 300,000 customers put their trust in the company’s pneumatic and electric drive products and technology.

In addition, Festo Didactic provides state-of-the-art training equipment and educational programs for industrial companies and educational institutions – about 56,000 customers worldwide. The Festo Group registered sales of €3.81 billion in the 2022 financial year and is represented worldwide at 250 locations with about 20,800 employees. About 7% of its annual turnover is invested in research and development.

More Information

Related Product

Festo Introduces Its Most Compact Parallel, Angled, and Radial Grippers

From recently completed production lines, Festo introduces a new generation of competitively priced compact grippers that offer a host of advantages for precision electronics and small part assembly. The DHPC parallel gripper offers ≤ 0.01 mm repetition accuracy, while its variants – the DHWC angle and DHRC radial gripper – offer ≤ 0.2 mm accuracy. The DHPC, DHWC, and DHRC are interchangeable with competitive grippers. They provide the added benefits of smaller size, higher grip force, long service life, and improved precision.