FSR’s 8K Next Generation Digital Ribbon Cables: The Ultimate Solution for High-Speed Signal Transmission

March 8, 2023

Are you tired of slow and unreliable signal transmission? Whether you’re using it for entertainment, education, or business presentations, having high-speed and high-definition signal transmission is crucial. Fortunately, FSR has the perfect solution for you – the 8K Next Generation Digital Ribbon Cables. These advanced technology cables offer unparalleled speed and reliability for various industries, including audio/ video, datacom, hospitality, education, and government.

Why Do You Need 8K Digital Ribbon Cables?

The digital world is constantly changing and evolving, and signal transmission technology is no exception. With the increasing demand for high-speed and high-definition signals, traditional cables can no longer keep up. That’s where 8K digital ribbon cables come in. These advanced technology cables allow for high-speed and high-definition signal transmission over long distances without signal loss or delay. They can easily handle up to 8k 60Hz 4:4:4 HDR uncompressed HDMI® video and are eARC compatible, providing the most vivid and realistic visuals for your entertainment, education, or business presentations.

Links:

- 8K Digital Ribbon Cables Product Page

- Digital Ribbon Brochure

- Next Gen 8K DR Cable Spec Sheet

- 8K CoilGuard Digital Ribbon Cables

- Next Gen 8K DR CoilGuard Spec Sheet

8K HDMI – Next Generation Digital Ribbon Cables with CoilGuard™

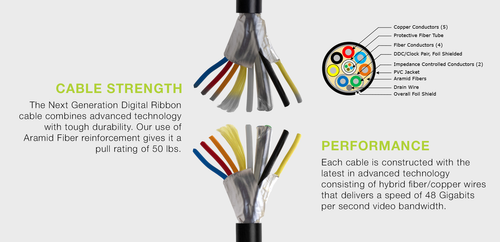

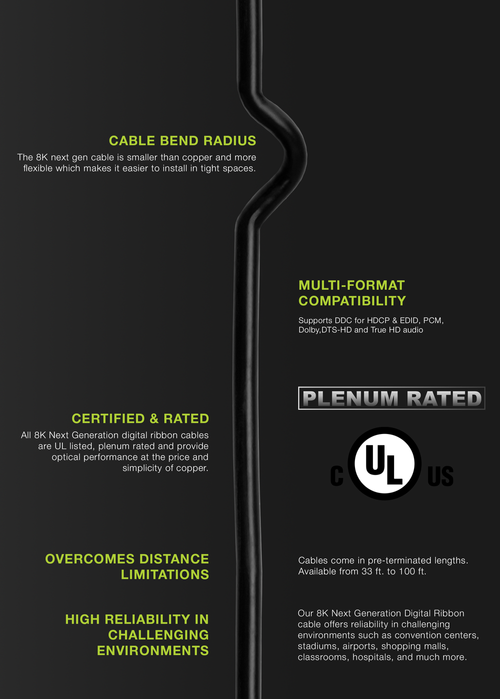

Our 8K Next Generation Digital Ribbon Cables with CoilGuard™ utilize a proprietary technology to allow high-speed and high-definition HDMI® signal transmission over distances of up to 100 ft. The CoilGuard™ is suitable for rough service and has a short-term load limit of 2000N/100mm (450lbs./4″). This durable cable is fitted with a stainless steel reinforced inner jacket and a discreet outer black jacket that allows the cable to withstand rough service and blend in after installation.

Features:

- Speed of 48 Gbps video bandwidth when directly connected or 18 Gbps when 6′ copper cables are added to ends

- Easily handle up to 8k 60Hz 4:4:4 HDR uncompressed HDMI® video

- Advanced technology uses four glass fibers, seven copper wires, and supplies the necessary power to the embedded circuitry at both ends of the cable

- Meet the HDMI® and HDCP testing standards

- Connector shells are labeled “source” and “display” to aid in proper connections

- Pre-terminated in convenient lengths

- Suitable for rough service with a short-term load limit of 2000N/100mm (450lbs./4″)

USB 3.1 Gen 2 Type-C Digital Ribbon Cables

FSR’s USB 3.1 Gen 2 Type-C Digital Ribbon cables are designed for high-end peripheral devices that use a USB Type-C connector to transfer data. The hybrid fiber/copper cables deliver a speed of 10Gbps data transfer without signal loss or delay, making it ideal for USB-C cameras, hard drives, PCs, or laptops. These cables are fitted with a discreet black jacket with the connector shells being labeled “HOST” and “DEVICE” to aid in proper connection.

Features:

- Speed of 10Gbps data transfer without signal loss or delay

- Suitable for USB-C cameras, hard drives, PCs, or laptops

- Connector shells

- Connector shells labeled “HOST” and “DEVICE” to aid in proper connection

- Enhanced Pull Strength of 15kg/33lbs

- Plenum Rated – Type CMP/FT6

- Supports Windows & Apple iOS

- Plug & Play without the need for software

- Supports USB 3.1 Gen 2 10Gbps data rate

- Power Transfer Limit of 5V/900 mA

What is CoilGuard™ Technology?

CoilGuard™ is a proprietary technology used in FSR’s 8K Next Generation Digital Ribbon Cables with CoilGuard™. It is a special feature that ensures the cables are suitable for rough service with a short-term load limit of 2000N/100mm (450lbs./4″). The technology utilizes a stainless steel reinforced inner jacket and a discreet outer black jacket that allows the cable to withstand rough service and blend in after installation.

The CoilGuard™ technology allows FSR’s 8K Next Generation Digital Ribbon Cables to be ideal for use in harsh environments where other cables might not hold up. With this technology, the cables are designed to withstand the wear and tear of daily use while delivering unparalleled performance.

Source Available Here