Automation and Control Systems, LLC Digitalizes Panel Modification and Wire Processing for Increased Productivity and Growth

November 25, 2022

As a full-service control systems integrator, Mississippi-based Automation and Control Systems, LLC (ACS) was facing a handful of common yet critical challenges in modifying, assembling, and wiring industrial panels. Labor shortages, time-consuming manual tasks, and legacy design and engineering programs made it difficult for ACS to scale their business and expand their footprint as a state-of-the-art system integrator and panel shop.

Plus, emerging market forces such as supply chain disruptions and increases in shipping costs accelerated the need for modification and assembly process automation, as well as a digitalized design and engineering platform that simplified alterations and revisions to panel schematics.

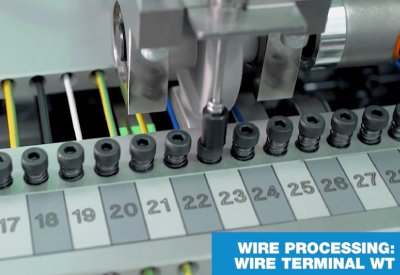

In order to overcome these hurdles, ACS partnered with Rittal and our Rittal Automation Systems (RAS) suite of panel and wire modification machines to optimize workflows through more detailed and precise cuts, drilling, hole punching, and wire processing and crimping. Rittal’s Perforex MT milling machine and Wire Terminal processing center helped reduce labor costs by 75% and gave ACS the capability to facilitate multiple tasks simultaneously while still ensuring a high-quality end product for their customers.

Combining the Perforex’s automated panel modification with Eplan’s CAE platform further increased productivity and efficiency through detailed 3D modeling, digital twins, and real-time design changes. In addition, bringing together Rittal’s Wiring Terminal, WT-36, and EPLAN’s Smart Wiring platform created a digitalized, fully automated wire processing ecosystem that reduced errors, saved time, and helped overcome labor shortages.

Watch this video to see how Automation and Control Systems, LLC Digitalizes Panel Modification and Wire Processing

{videobox}5e70rx9tJtg{/videobox}

“Integrating the RAS equipment with Eplan allowed us to automate our workflows at every stage, from the engineering process to the shop floor,” said ACS President, Clay McNutt. “One engineer is able to complete multiple tasks at any given time and this efficiency has helped us provide a better product for the end-user.”

In addition, Rittal’s Wire Terminal and EPLAN’s Smart Wiring platform allowed ACS to upgrade the panel wiring process, a manual task that can typically account for up to 49% of enclosure processing. Manual panel wiring can be automated to increase workflows up to 8X faster with Rittal and Eplan technology. Capabilities of the WT-36 include selecting wire type, printing on the insulation, cutting to length, stripping the insulation, and crimping the ferrules. The wires are then deposited to a wire rail and kept in sequence for subsequent work steps.

This automated wiring technology has enabled ACS to meet the increased demand of their current customers and bring in new customers that they wouldn’t have been able to support without the RAS machines and Eplan technology. Precious resources previously used in manual tasks are freed up with the switch to automated solutions – the technician’s time can be used to complete additional projects.

To streamline the wiring process, design the wire routing in EPLAN Pro Panel and export the file to the WT-36 which builds the sequence creating an optimized workflow for panel wiring. The 3D wiring guidance of EPLAN Smart Wiring is synchronized with the processed wire for an optimized 1:1 workflow. This technology streamlined the panel wiring process for ACS by providing the exact wire path needed and allowed their technicians to move faster and more accurately.

“Without the combination of EPLAN Smart Wiring and the WT-36 our team wouldn’t have the tools for the automation, speed, and precision our customers require” states McNutt. McNutt credits the vertically integrated nature of the RAS suite and its ability to create a more connected value chain with allowing ACS to partner with customers they otherwise would have been unable to serve.

“Since integrating the Perforex, WT-36, and EPLAN, we’ve taken on multiple customers that require high volume work and consistent repeatability,” said McNutt. “Automating the panel building process with Rittal has made it possible for us to take on these projects and grow our business.”

Aside from helping to combat labor shortages and costs, the combination of the Perforex MT, the WT-36, and Eplan helped ACS seamlessly adapt to a new, industry-wide paradigm shift in panel design and building: digitalization in modern manufacturing.

McNutt also feels partnering with Rittal and Eplan on an automated panel modification and assembly system makes it easier than ever before to accomplish their most foundational goal: Providing their customers with the products they need to succeed.

“We’re able to do more work in less time with a much higher degree of quality,” said McNutt. “Rittal and Eplan have allowed us to accomplish that.”

To learn more about how Rittal’s RAS suite can help you increase your panel building and wiring efficiency by 85%, click here