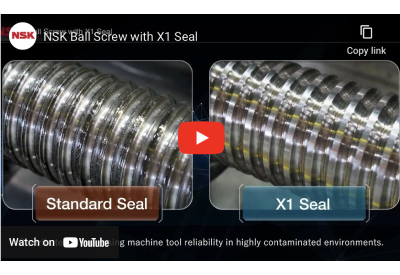

NSK Ball Screw with X1 Seal

November 17, 2022

{videobox}Zki3yV3NuuM{/videobox}

X1 seal achieves both high contaminant resistance as well as high grease retention thereby improving machinery reliability. The X1 seal further improves sealing performance, thereby contributing to extending machine tool maintenance cycles and reducing environmental impact.

Benefits: 1.Optimized seal lip design achieves both high dust resistance and low friction. Reduces entry of foreign matter to 1/30th of NSK’s standard seal, contributing to the long-term stable operation.

2. Designed with highly wear resistant material for long term sealing performance. X1 achieves excellent sealing performance over a long period. Enables a reduction in lubrication amount, and reduces grease splatter. Ideal for use with automated lubrication systems.

3. Contributes to increasing machine tool reliability in highly contaminated environments. Optimized seal shape also reduces torque arising from the seal

To learn more, click here