Extremely Compact ArcWorld Workcells Easily Integrate Robotics into Weld Processes by Yaskawa

June 16, 2022

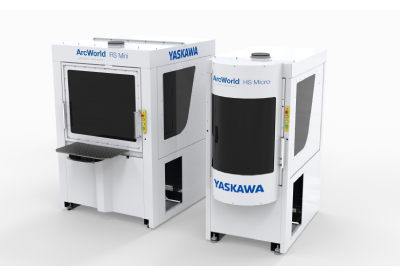

The newest models of the ArcWorld® family of pre-engineered robotic arc welding workcells, the ArcWorld RS and ArcWorld HS, deliver a highly flexible, compact and cost-effective option for integrating robotics into current weld processes. Ideal for replacing or supplementing manual welding, such as pre-assembly before welding in larger robotic workcells, each solution is designed for optimizing small- to medium-size part production for medium volume fabrication.

Requiring only 2.3 square meters (25 sq ft) of floorspace, the ArcWorld RS utilizes a rotating station (RS) design, manually indexed by the operator, featuring two fixture tables with a 100 kg payload capacity per side. This facilitates quick changeover, allowing parts to be safely loaded and unloaded while the opposite station part is welded. Parts up to 425 x 700 x 990 mm can be processed.

More compact, the ArcWorld HS needs only 1.4 square meters (15 sq ft) of floorspace and offers a hinged station (HS) design, allowing easy access for loading and unloading of parts. The workcell features a single fixture table with a 100 kg payload capacity and can process parts up to 550 x 500 x 1,050 mm in size. This cell is ideal for R&D and educational use as well as smaller production runs.

Each ArcWorld features a single high-speed, six-axis AR900 arc welding robot with YRC1000 controller. An intuitive digital weld interface for all power source brands is included. An integrated weld package includes either a Miller® Auto-Continuum™ 350 or Lincoln Electric Power Wave® R450 power source, wire feeder, wire spool holder and a variety of available torch options. Processes from the power supply are accessed by Yaskawa’s easy-to-use digital Universal Weldcom Interface (UWI), giving full control of welding parameters and settings from the robot programming pendant.

Each solution offers overhead LED lighting and is enclosed with sheet metal and light-reducing polycarbonate for arc and spatter protection. A built-in extraction hood for fume filtration and four-button operator panel with E-stop also come as standard.

The ArcWorld RS and ArcWorld HS are safeguarded and have a completed risk assessment compliant with ANSI/RIA R15.06-2012, and other relevant ISO and CSA standards. The robot controller’s Functional Safety Unit (FSU) uses “stand still” monitoring for the robot and safety signals. All workcell doors are safety monitored.

Each workstation, including the robot and safety fencing, come attached on a common base with integrated cable management for easy shipping and installation. Easy-open, safety-interlocked side panels allow for easier robot programming and equipment access.

Additional optional features are available, including a light beacon (3 color), Digital TouchSense, gas flow rate meter (CWT) gas flow sensor (SMC) and a torch cleaning station (with or without wire cutter).

To learn more about the ArcWorld® family of pre-engineered robotic arc welding workcells from Yaskawa, visit their product page by clicking here