Akribis: Frameless Direct Drive Rotary Motors Offer Many Benefits

October 14, 2021

When it’s time to specify a rotary motor for a space-constrained assembly, size and weight will factor into your decision. After all, you’ll want to get the best motor performance possible for the available space, and you’ll also want trouble-free integration into the system. Larger, heavier motors tend to be inefficient and can limit design flexibility. And, choosing the wrong motor can be costly. This article will describe a style of motor that is both compact and highly efficient, making it desirable for a wide range of precision machines and other space-limited applications.

One way to save space is to eliminate the housing of the motor. This allows the rotor and the stator to mount directly to the assembly without the housing components that consume space and are typically sources for energy losses. The result: an efficient system that economizes both space and costs. Akribis Systems’ low-cost, ironless ADR-T family is one such example of a high-performance, frameless, brushless direct drive rotary motor. Here are some of the advantages of the ADR-T family:

- – Compact size. These frameless motors are available in two sizes. Customers can choose a 50-millimeter outer diameter with 14-millimeter stack height, or an 80-millimeter OD with 20-millimeter stack height. Despite their small sizes, both units offer a generous inner bore size. Their compact size makes them easy to integrate while keeping assembly sizes smaller and lightweight.

- – High torque density. ADR-T motors pack more torque into a smaller unit, and they exhibit a higher torque constant versus similar frameless motors on the market. This combination of high torque density and their effective conversion of electrical power to mechanical power makes these frameless motors exceptionally efficient.

- – Cost advantages. This motor family costs less than previous Akribis rotary motors of a similar size, and the cost advantage increases with higher quantities. And, their easy integration means customers save both time and labor costs.

- – Additional features and specifications. In addition to these benefits, ADR-T motors also feature rotating speeds up to 4,000 rpm, low cogging torque, a maximum working temperature of 130°C, and they’re appropriate with low- and high-speed windings.

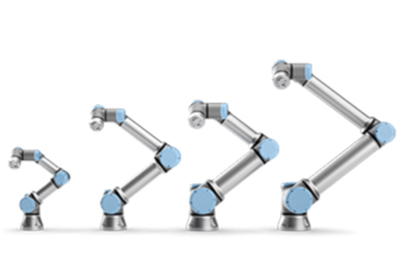

These features and benefits make ADR-T frameless rotary motors well-suited for use in operating conveyors, presses, robotic joints, pick-and-place machines and other material handling and packaging equipment as well as servomechanism applications.

Build More Efficient, Cost-Effective Mechanical Systems

Frameless motors allow machine builders to overcome the size limitations of their designs while offering high performance and efficiency. And, they are low cost and easy to integrate. To find out if frameless, brushless direct drive rotary motors like the ADR-T Series are right for your automated system or other industrial application, be sure to contact Akribis Systems to talk to a technical expert.