Advanced Motion Controls Releases the FM060-25-CM Micro-Sized High-Power Servo Drive

February 8, 2021

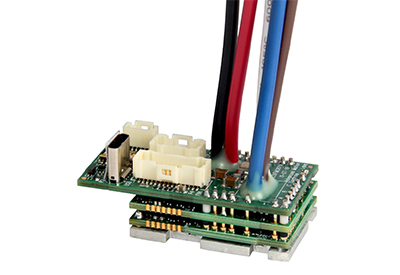

The FM060-25-CM is part of a new breed of micro-sized, high-power servo drives, immediately available from ADVANCED Motion Controls. Rated to output 25A continuous and 50A peak, this fully featured digital servo drive is small enough to fit in the tightest locations. It is ideally suited for mobile and portable applications such as mobile robotics, automated mobile robots (AMRs), AGVs, material handling, warehouse automation, lab automation and more.

The mounting footprint of the FM060-25-CM is 50.8mm x 25.4mm with a height of 22.1mm making it possible for up to 3 units to fit within the footprint of a standard business card. The FM060-25-CM uses CANopen for network communication. Along with this model are two lower current options, the FM060-10-CM rated to 10A continuous and FM060-5-EM rated to 5A continuous, designed to the same dimensions.

Features include:

- 8 x 25.4 x 22 mm (2 x 1 x 0.87 in)

- 10-55 VDC input

- 25 A continuous, 50 A peak for FE060-25-CM

- 10 A continuous, 20 A peak for FE060-10-CM

- 5 A continuous, 10 A peak for FE060-5-CM

- Incremental encoder and BISS C-mode feedback

- Torque, velocity, and position operating modes

The FM060-25-CM can be configured to work with any servo motor because the control loops for Current, Velocity and Position can be individually tuned to match the application’s motor, load inertia, supply voltage and motion requirements.

Once configured for the system, the FM060-25-CM can be controlled over a CANopen network using PVT commands or profile motion commands. It can also be commanded using analog signals, indexes & sequences, step & direction, and encoder following. Despite its small size, no feature or capability has been spared when compared with full-sized counterparts.

Information on the FM060-25-CM can be viewed at: https://www.electromate.com/fm060-25-cm/.