Teradyne Robotics and Honeywell Team Up

June 2, 2025

Teradyne Robotics and Honeywell Team Up to Help Companies Automate Material Transport and Successfully Scale Automation Solutions

- Collaboration will deliver intelligent automation, including autonomous mobile robots, to logistics and supply chain businesses, boosting productivity, reducing operational costs and improving worker safety.

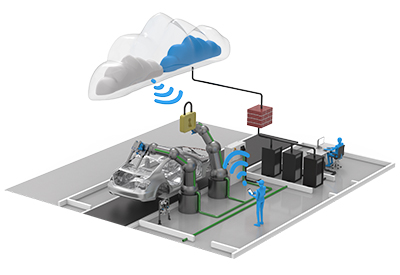

Teradyne Robotics is teaming up with Honeywell to deliver automation solutions for logistics, warehousing and fast-moving consumer goods companies throughout the Americas and Europe. The collaboration brings Teradyne Robotics’ autonomous mobile robot (AMR) and collaborative robot (cobot) technologies together with Honeywell’s advanced software, extensive implementation expertise and cybersecurity capabilities.

“This relationship with Honeywell will provide businesses with end-to-end solutions, from automation system design through to implementation and maintenance,” said Ujjwal Kumar, Group President of Teradyne Robotics. “The combined strengths of Teradyne Robotics and Honeywell will help companies tackle the challenges they are experiencing today with labor-intensive, inefficient material-handling tasks.”

Teradyne Robotics — which encompasses Mobile Industrial Robots (MiR) and Universal Robots — has shipped more than 110,000 advanced robots to companies across the globe. Its portfolio of robotic solutions includes infrastructure-free AMRs that take on previously manual, low-value tasks like transporting material throughout a distribution facility or lifting and moving heavy pallets, freeing employees up for more strategic work. Teradyne Robotics’ advanced robotics platforms are also used for AI-enabled applications, guiding motion, optimizing paths and performing complex tasks with precision. Its MiR1200 Pallet Jack uses an AI-based perception system to detect and move pallets within large warehouse facilities, reducing pick-and-place times and significantly increasing throughput.

With more than three decades of experience, Honeywell brings deep warehouse automation expertise, enterprise-level software capabilities and a comprehensive system of integrated services to the partnership. Honeywell’s Momentum Warehouse Execution Software (WES) empowers businesses to adapt to dynamic demand shifts, orchestrating interoperability among diverse robotic point systems while optimizing material flow and processes.

This new collaboration combines Teradyne Robotics’ advanced solutions with Honeywell’s Momentum WES, resulting in comprehensive, customer-focused material handling and process optimization as well as seamless, intelligent automation that tackles material transport challenges while scaling automation across operations. Businesses stand to benefit from reduced operational costs, streamlined workforce operations and enhanced productivity—all while prioritizing employee safety and satisfaction.

“Honeywell’s relationship with Teradyne Robotics empowers operations in distribution centers and warehouses through end-to-end automation solutions that enhance operational efficiency, optimize resources and improve worker safety,” said Chad Briggs, president of Honeywell Intelligrated. “Together, we’re making automation adoption accessible and impactful for organizations, enabling them to focus on strategic goals and drive tangible results.”

Related Story

Artificial Intelligence (AI) Integrates with Cobots and AMRs Making them Smarter

Robot technology is becoming increasingly accessible for companies of all sizes across a wide range of industries. Accelerated computing and the ever-evolving contribution of artificial intelligence or AI are transforming virtually everything – robots and robot technology included. Teradyne Robotics, a global leader in advanced automation solutions and parent company to Universal Robots (UR) and Mobile Industrial Robots (MiR), introduce their new AI-enabled collaborative robot arms and autonomous mobile robots.

Anders Billesø Beck, VP of Innovation and Strategy at Universal Robots, discusses the integration of AI into collaborative robots (cobots) and autonomous mobile robots or AMRs, and the benefits that AI can bring to robotic applications and the industries they serve.

Beck admits that many of the challenges faced in robotic applications stem from the fact that robots are not humans. Making applications reliable, despite variations in the environment or task, remains a complication for robots that he says can be aided with AI. If this is possible, there will be virtually no industry that will not benefit from it today. “What AI can do today, and will be doing more in the future, is to have that sort of human-scale capability of seeing things and even generating the behaviour of what it would take to grasp or react to whatever it sees.”