ABB Invests in Made in Canada with Installation Products that Electrify Our World

August 18, 2025

By Krystie Johnston

ABB recently announced their plan to build a new R&D and manufacturing facility in Canada. It will combine their existing facilities in Iberville and Saint-Jean-sur-Richelieu to increase production capacity and support future growth in key sectors across Canada like utilities, energy, and infrastructure. Michael Shenouda, Canada Region Leader – General Manager, Installation Products, answers my questions about the new facility. Shenouda started at ABB for a summer job, now, 30 years later, he plays a leading role in the company.

“I will start by saying that this is really the largest investment for ABB in Canada in all its history, whether as Thomas and Betts or ABB. It is an over $130 million dollar investment over the next two years to build the greenfield facility. We have purchased about 1,000,000 square feet of land in the Saint-Jean-sur-Richelieu city…. And we are going to build a 340,000 square foot facility with custom automation, advanced AMRs, and we are adding new technologies,” Shenouda says. “Once the [new] site is completed, we are going to move the Iberville production and the Saint-Jean production into that site. We are really proud of that.”

Shenouda says this investment is part of ABB’s ‘Local for Local’ strategy, and they are making similar investments in other countries too. “ABB has always had a strategy – whether it is in Canada, US, Mexico, or the rest of the world – to produce its goods locally, where customers create the demand,” he says. “For us and ABB Installation Products, 80% of what we deliver to customers [in Canada] is actually built in our facilities in Canada. ABB as a whole has 33 sites; Installation Products has six manufacturing sites, two warehouse distribution centres, and sales offices across Canada. We are very proud to be manufacturing our goods in Canada.”

“Made in Canada” is something that ABB strives for. It is something they promote. And they have been doing this for decades. “It is something we are proud of,” Shenouda says. “I think the pandemic has proved that having robust supply chains close to where customers’ needs are is very important. We source all our steel locally; within 500 kilometers of the factories we operate. Our aluminum is mostly Canadian as well. We are very proud to have 600 employees in both our Iberville and Saint-Jean facilities.”

Shenouda says this strategy, ‘Local for Local’ is what prompted them to acquire the land for the site where they did. The greenfield site is very close to ABBs existing sites, which enables them to retain 100% of their employees and ensure the continuity of their qualified workforce “We are trying to build a new factory that can ensure we maintain growth with the industry. We know electrical demand is increasing. That is putting pressure on the networks, the reliability of the grids, and so on. We supply electrical components that are used in everyday life. We want to make sure that we are well equipped to be able to supply that demand for the coming decades.”

ABBs commitments anticipate the future and the planet for generations. Their Installation Products Division, for example, has made similar investments across North America and around the world so they can be close to their customers. “I think ABB has proven their strategy of local for local. We are investing in every single country,” Shenouda says. “We have put in $375 million over the last decade in Canada. We have invested close to a billion dollars in the US, Mexico, and North America. In the Installation Products Division, we have added 90,000 square feet to our Alburquerque site in New Mexico. We have increased capacity in Hackettstown, New Jersey. And we have added equipment and machinery in Ormond Beach.”

ABB’s other divisions continue to invest as well. Their systems and drives and robotics divisions have been adding capacity over the years too. “The purpose of that investment is really to increase our foothold in the region, add capacity to be able to supply demand, and make sure we are keeping up with this demand that is growing – whether that is data centres, food and beverage, or utilities,” he says. And they invest in many ways. “In Canada, we are investing not only in our existing factories, but we are also adding portfolios. We did the acquisition of Bell Products a few months ago… we partnered with Black Box Technologies late last year. And we also did a joint venture with the Niedax Group [around the same time].”

“I think ABB has always invested [strategically]. And we are going to continue to do that in the coming years,” Shenouda says. ABB also continues to reinvent itself as it grows amidst a changing world. They recently rebranded with a new slogan: ‘Engineered to Outrun’ emphasizing their commitment to helping industries be more productive, efficient, and sustainable. “We want to help our customers run leaner and cleaner. We want to supply our customers with the best possible technologies and products to make sure that they can outrun their competitors as well.”

Shenouda says to do that, they invest in their own facilities to ensure they are at their peak, and they innovate constantly. “In our new site we are also adding a Customer Experience Centre where we are going to be able to train our customers and our partners to use our products.” He says they are also increasing the size of their existing Canadian R&D centre in Canada. “We are trying to add new technologies in our own manufacturing sites to be able to help our customers run leaner and cleaner.”

ABBs’ commitment to their customers is like no other. And made in Canada means more than just words. For Shenouda, actions speak louder than words. “When we say ‘made in Canada’ we are very proud. We support it everywhere. But I am glad to see that we are actually building factories, we are making acquisitions we are investing in Canada, in local jobs. We are purchasing materials locally – we do not purchase our steel supply from India or China or anywhere else in the world – even if it would be cheaper.” These actions clearly demonstrate ABB’s commitment to Canada and the local regions.

The name of the facility has not been decided at the time of this writing. Shenouda says that marketing teams and ABB employees are participating in making suggestions and selecting the top five names. It will be announced when it is decided.

Shenouda says that it is already decided what products are going to be made in the new facility: electrification products that support the increasing demand for energy. “The demand on the grid is increasing year-over-year. Whether it is data centres or utility demand. In some regions, investment is limited due to the grid’s inability to supply enough energy. “Our products are used in everyday life. Wherever you have electricity, you can find ABB products.”

“This investment helps us to be able to supply components throughout the next few decades, and make sure that we are a trusted partner for our customers. It is going to support the grid we have,” Shenouda adds. He says that they will be producing electrical boxes, Star Tech Connectors, Microelectric meter enclosures – products that are used to supply households, data centres, or industrial applications and power our everyday lives. “All of those components are going to be moved to this new facility. And we have added 30% additional capacity – and we are going to be adding more lines to that site to be able to produce new components down the road.”

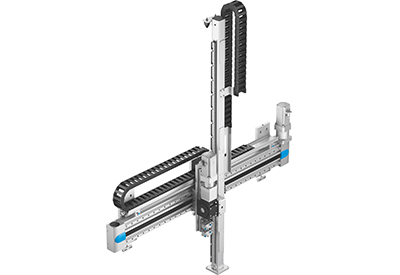

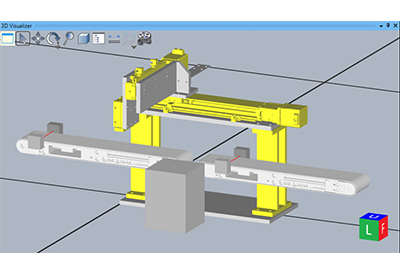

ABB will use their own technologies to leverage automation and ensure their productivity meets demand. Shenouda says the Iberville and Saint-Jean facilities already use automated lines. “We are going to continue to add and invest in new equipment for this new site. We are replacing some older lines. We are actually doubling capacity for certain product lines to be able to keep up with demand. And we are going to be increasing the number of robotics and automated workcells throughout the facility.”

Shenouda says they are very proud to be investing this much in Canada. “We have been in Canada for over 100 years. We are proud to be Canadian manufacturers. We have 3,300 employees in Canada under the ABB umbrella of brands, and for Installation Products, we have 1,400 employees, most of whom are in Quebec. Made in Canada has always been part of our DNA,” he says. “It is going to be an interesting two years to build this factory and be able to move our equipment from our existing sites. But we are looking forward to it. It is a great adventure, and we are setting the foundation for the next few decades to be able to supply our customers with great products.”

More Information

Related Story

ABB Invests More than CAD 130 Million in R&D and Manufacturing in Canada

ABB announced on August 5 that it will invest more than CAD 130 million (approximately USD 100 million) to expand research, development, and manufacturing capacity for its advanced energy protection and grid resilience technologies in Canada. The investment in Montreal, Quebec, will consolidate ABB’s existing factories in Iberville and Saint-Jean-sur-Richelieu into a new site. This will enable ABB to meet growing demand in key growth sectors, including utilities, renewable energy, transportation, residential, and infrastructure projects across Canada.