Maintenance Safeguarding “Key In Pocket’ System From PILZ Protects Against Restart And Tampering – Safe And Secure Plant Maintenance

October 6, 2022

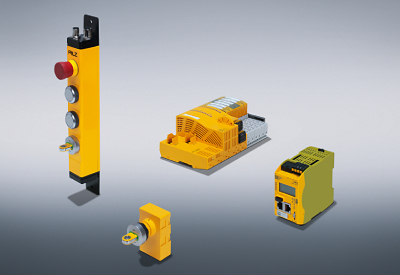

The new maintenance safeguarding “key-in-pocket” system from PILZ protects operators from an unauthorized machine restart, allowing maintenance work to be carried out safely. Digital maintenance safeguarding is based on the access permission system PITreader and guarantees safety and industrial security: only authorized persons can access the plant or machine during the maintenance process – tampering and misuse are excluded.

Extensive plants often have a large number of danger zones, which are protected using safety fences. This places particular demands on safety: for example, it’s important that only authorized persons have access for maintenance work. At the same time, it’s essential to ensure that nobody is left in the danger zone when the plant restarts.

With “key in pocket,” PILZ is presenting a digital maintenance safeguarding system, which is flexible in meeting the demands of both safety and industrial security: “key in pocket” ensures that the machine does not restart while maintenance work is being carried out and that unauthorized persons do not gain access. As such, the solution offers safety in the face of a hazardous restart and, at the same time, industrial security, because it’s impossible to tamper with the maintenance work.

Authentication as the basis

“Key-in-pocket” is based on the access permission system PITreader and is implemented using the configurable small controller PNOZmulti 2 or the automation system PSS 4000. Users are given an RFID key with their individual permissions, which can be read on the safety gate using PITreader. This way, one or more users who are authorized for maintenance work can authenticate themselves on the plant. At all times, the operator knows who has access for which task; temporary permissions can also be assigned. After successful authentication, a personalized security ID is stored for the user in the controller, in a safe list. The machine can now be shut down, the safety gate opened, and the machine accessed. During this time, the RFID keys remain with the respective users – “key-in-pocket”. Once maintenance is complete and people have left the danger zone, everyone signs out. The security IDs are removed from the safe list on the PILZ controller, and the machine can be restarted.

Simple, safe maintenance

Digital maintenance safeguarding is specifically designed for machines with danger zones that are protected via safety fences. It offers an economical, efficient alternative to mechanical lockout-tagout maintenance safeguarding systems, which are attached to all safety gates. As it is possible to enter or leave the plant via various safety gates, “key-in-pocket” offers staff greater flexibility and thus saves time during maintenance.

To learn more about these products, visit PILZ’s website by clicking here